The Best Supplier of 26/22 Neck Preforms in Gujarat

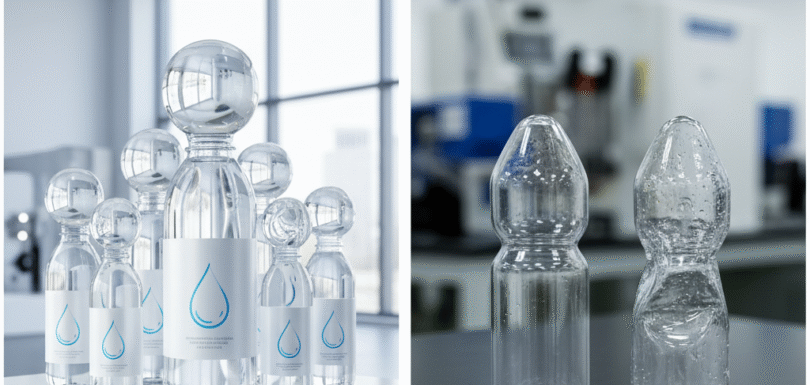

The Packaging Industry in India has become a very important industry for India as it encompasses bottled water, juices, carbonated soft drinks, and household items; however, all of these items rely on the very foundational item of strong, safe, and reliable preforms made from PET (Polyethylene Terephthalate) plastic, which are used in the making of bottles. Of the many different types of preforms available in the growing market, the 26/22 neck preform has become one of the most popular formats used today by many manufacturers. In this blog, we will explain simply what these preforms are, why they are important, and why DRJ has consistently been ranked as the best preform manufacturer and the leading supplier of 26/22 neck preforms in Gujarat. What is a 26/22 Neck Preform? The 26/22 preform is a semi-finished item made out of PET (Polyethylene Terephthalate) plastic that resembles a test tube that has a screw thread neck. After this preform has undergone a blow-molding process, it will be transformed into a final product (bottle). The terminology 26/22 represents the dimensions of the neck, which consist of two measurements: (26 mm) for the diameter of the mouth, and (22 mm) for the height of the screw thread. The 26/22 preform is the backbone of the bottled drinking water and carbonated beverage industries. Why PET Preforms Are Important in Packaging The most widely used packaging material is PET (Polyethylene Terephthalate). It is lightweight, durable, easy to recycle, and safe to use for food products. The PET packaging market in India has been estimated to be approximately $1.9 billion in 2023 and is projected to see 6.3% annual growth rate through 2026, according to Mordor Intelligence (2023). PET preforms are critical for the production of bottles of all shapes and sizes. Without PET, it would be impossible to consistently produce the same quality of bottles for mass production in: The Growing Demand for 26/22 Preforms in India The bottled water market in India has grown to become one of the largest markets for bottled water in the world, and as of 2022, the Bureau of Indian Standards (BIS) has reported that there are approximately 1,400 bottled water manufacturing facilities across the country. The primary source for the majority of this manufactured product comes from the state of Gujarat due to the heavy concentration of manufacturing and production facilities that are available. The packaged drinking water segment is expected to reach INR 403 billion in value by the year of 2026, growing at over 20% per annum according to Rajesh and Partners (2023). The primary drivers for this growth include an increase in urbanization, modernization of lifestyles, and an increasing focus on the hygiene aspects of daily diet choices. The growth in this sector will create additional opportunities for suppliers of 26/22 preforms. DRJ – The Biggest PET Preform Manufacturer in Surat In Surat, Gujarat, DRJ has earned the title of the top PET preform supplier in its region due to the time and resources invested in upgrading equipment and implementing stringent quality assurance policies. Organizations that utilize the services of DRJ select DRJ because of: How DRJ Stands Out from Market Standards Numerous companies are offering PET Preforms in Gujarat, but DRJ is distinguished from the others by the following: Applications of 26/22 Neck Preforms In order to fully understand how these preforms translate into finished products on the marketplace, let us take a look at what products people use daily. Packaged Drinking Water Bottles – The most significant use of 26/22 preforms is packaged drinking water bottles, being manufactured by most of the manufacturers, and most commonly found as 500ml and 1l water bottles. Soft Drinks and Carbonated Beverages – Major soda manufacturers also utilize PET preforms of this size when manufacturing their beverage bottles. Juice and Energy Drinks – This size is also suitable for medium-sized juice bottles as well as small-sized juice bottles. Edible Oils and Other Liquids – Some oil and liquid condiment manufacturers utilize bottles in this size for their products. As an example, the Indian bottled water industry alone consumes millions of PET preforms daily, and if suppliers like DRJ did not exist, this supply demand could not be satisfied consistently. Real-World Impact of PET Preforms The Packaging Industry Association of India (PIAI) estimates that packaging is the fifth-largest sector in India, currently growing 22–25% each year (PIAI, 2023). The result of this growth is a significant increase in the demand for manufacturers producing PET preforms. India’s per capita consumption of bottled water has grown from ~5 litres 10 years ago to ~25 litres per person each year (India Water Portal, 2022). Most of the water is supplied in bottles using 26/22 neck preform bottles. As a result, the need for a dependable 26/22 preform bottle supplier in Gujarat has never been greater. Why DRJ is the Best PET Preform Manufacturer for You Businesses looking for a manufacturer of PET preforms in Gujarat will want to find a manufacturer that has a combination of experience, technology, and service. DRJ can meet all of these criteria by offering: To Wrap Up The 26/22 neck preform is an essential part of one of today’s most important packaged beverage industries; packaged beverages are growing at an unprecedented pace in India. With the rise of the packaged drinking water and soft drink industries in India, the demand for suppliers has never been greater. DRJ is one of the largest PET preform manufacturers in Surat and is considered to be a top performer in Gujarat for 26/22 neck preforms. Through providing consistent quality, bulk manufacturing capacity, and superior service to our customers, DRJ has rightfully earned its reputation as the best PET preform manufacturer in Gujarat. If you are looking to secure your packaged beverage supply chain, DRJ Plasttech is not only a supplier but also a long-term growth partner.