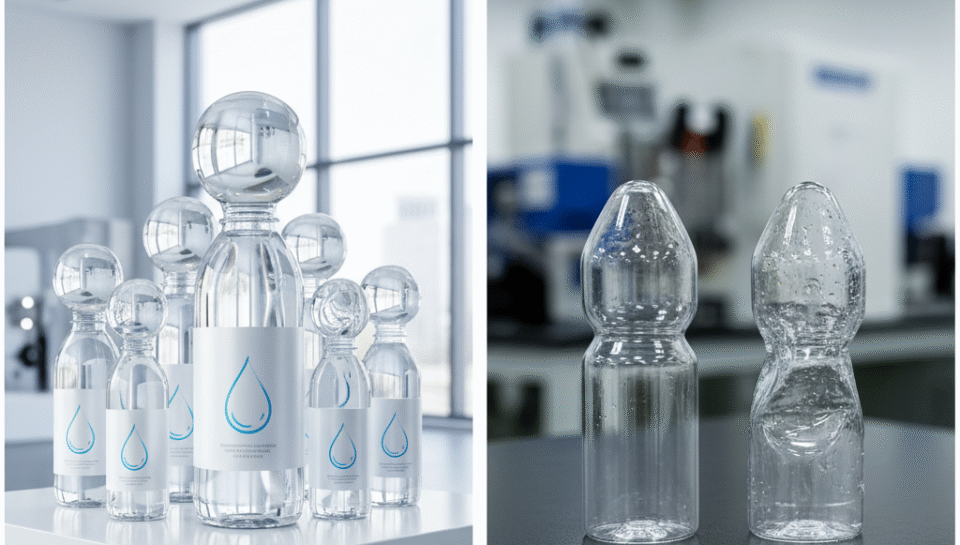

The packaging industry continues to grow at an incredible rate, and one of the most important products in this growth is also the most recently developed: the Bubble Top Bottle. These large volume containers are now commonplace in homes, restaurants, offices, and gyms, as they allow people to access clean, sanitised, and safe drinking water easily; however, many people may not realise that the plastic bottle preform is an integral piece of this great development.

Bubble top preforms do not merely serve as the initial shape of their respective bubble top bottles, but rather they define the weight distribution, overall strength, clarity of the product being stored inside, and, lastly, whether or not the cap will work on that particular bottle. In fact, choosing the appropriate preform can prevent leaks, breakage, and lost revenues due to improperly designed preforms.

In this blog, we will examine trends in bubble top bottle design, along with the importance for every beverage company to have a solid understanding of the different types of plastic preforms in use today for bubble top bottles.

Table of Contents

- Why bubble top bottles are in demand today

- Role of preforms in bubble top bottle manufacturing

- Top design trends shaping the bubble top bottle industry

- How plastic preform choice makes or breaks a bubble top bottle

- Key plastic preform types for bubble top bottles

- Mistakes to avoid when selecting a preform

- Future innovations in preforms and bottle design

- Final thoughts

Why bubble top bottles are in demand today

The so-called “Bubble Top” bottle has become an established component of bulk water delivery systems. It’s a bottle:

- Large enough to hold between 15 -20 litres of liquid (ideal for both commercial and residential)

- Reusable and therefore a much more environmentally sustainable option than single-use bottles.

- Compatible with Water Dispensers; consequently suitable for hydration systems at both homes and in workplaces.

The expansion of cities and urban centres, an increase in public knowledge about health/fitness, and the proliferation (via organisation) of such services have also resulted in increased demand and competition for this product. Additional brands are now entering the packaged water segment, which means improved design and durability of these bottles have become vital to differentiate themselves from their competitors.

Role of preforms in bubble top bottle manufacturing

The preform is essentially the first step in manufacturing every bubble top bottle, so it is vitally important that it is designed and created correctly. If you take a look at large-capacity bottles, the quality and weight of the preform’s material, as well as its design, will play a significant role in producing the finished product.

The preform plays an important role in several key areas of the production of bubble top bottles:

- Structural integrity: The preform will provide enough structural support so that the bottle can endure the pressure generated by the large quantity of water.

- Visual quality: The preform determines the visual appearance of the bottle, including how clear the bottle is and whether it appears to be a premium product.

- Compatibility: The preform ensures that the closure for the bottle will properly seal to prevent leakage.

- Efficiency: The preform helps the production process run efficiently through the blow-molding and filling processes.

Essentially, while the preform is considered a raw material, it is actually an integral part of developing a product that will perform well.

Top design trends shaping the bubble top bottle industry

With the rise in what consumers expect from packaging, the bubble top bottle design has also advanced with new design innovations. Currently, there are five key trends shaping the designs of bubble top bottles:

1. Lightweighting for cost efficiency

Beverage manufacturers are requesting bottles that are lighter in weight yet still sturdy. Lighter bottles result in lower materials costs, plus less weight to transport.

2. Enhanced ergonomics

As the shape and finish of the neck are more ergonomic to lift and pour, the bubble top bottle design has become much more ergonomic than before.

3. Sustainable design with rPET

Preforms for plastic bottles are being developed with a focus on sustainability, incorporating rPET in order to have less environmental impact. Eco-conscious consumers are looking for preforms that are designed sustainably.

4. Custom branding options

More beverage companies are designing custom-branded bottles with logos, unique shapes, and colouration, helping to differentiate them from similar products.

5. Durability under reuse cycles

Because of the increasing reuse cycles of bubble top bottles, manufacturers will continue to seek longer-lasting preforms.

How plastic preform choice makes or breaks a bubble top bottle

The performance of a preform dictates the strength, appeal, and cost-effectiveness of a bubble top bottle.

- If the preform has too little weight: The end product (the bottle) will eventually collapse due to lack of strength and create a stress crack.

- If the preform has too much weight: The end product will be over-manufactured in cost and not be competitive.

- If the preform has low clarity: The bottle will appear cloudy, creating a doubt in the consumer’s mind concerning the purity of the water.

- If the neck dimensions are not accurate: The cap will not fit correctly, causing leaks and waste.

For any company that is purchasing plastic bottle preforms, careful consideration must be given to the factors mentioned above. A slight error in the preform process can result in an increase in both production and distribution costs later on.

Key plastic preform types for bubble top bottles

Different types of plastic pre-forms aren’t the same, and your ability to choose the right type can greatly affect your success in the marketplace.

1. Standard PET Preforms

The most common type of plastic bottle pre-forms, these preforms are designed primarily to create “bubble top” type bottles for everyday purposes like delivering drinking water. They have a reasonable balance between strength and price performance.

2. Heavy Duty Preforms

With more thickness and weight than standard preforms, heavy-duty preforms are designed for high levels of reuse or excessive handling of the final product.

3. Lightweight Preforms

Lightweight preforms typically use less raw material to create the same structural supports that are present in the heavier versions. Because of this, they are popular in markets where customers are very price sensitive.

4. Recycled PET (rPET) preforms

Preforms produced from recycled PET resin, either partially or fully, meet environmental concerns about sustainability and offer good strength and clarity.

5. Specialty Preforms

These products are customised for specific branding needs. Specialty preform types may contain brand-specific colours, embossed logos, or unique neck finish requirements.

Mistakes to avoid when selecting a preform

Selecting the appropriate plastic bottle preform is important, but many organisations continue to make preventable mistakes which will ultimately affect bottle quality and profit margins. Below are the five major pitfalls to avoid:

1. Preform to bottle compatibility

Plastic preform types are not interchangeable across all mould designs. If the dimensions of a preform do not match the neck size of the bottle, there will be problems creating acceptable bottle products, and moulds may reject the batch.

2. Cost is the only consideration

When a company chooses the cheapest preform available, they typically sacrifice quality in return for price. A preform made of poor quality plastic may cause the finished product to be plagued with cracks and leaks and have a high reject ratio, resulting in higher costs overall.

3. Weight optimisation

If a preform is either underweight or overweight, that preform may hinder overall production efficiency. A balance between the two will facilitate the production of a solid bubble top bottle and help to eliminate the chances of overspending on raw materials.

4. Inconsistent supplier quality control

Not all suppliers follow the same quality assurance practices regarding clarity, resin, and dimensional accuracy. Building a relationship with reliable preform manufacturers is necessary in order to prevent problems associated with poor performance.

5. Neglecting to consider sustainability

As both the regulatory environment and consumer preferences change, companies that ignore sustainable plastic preform materials (such as rPET) may struggle to remain competitive.

Future innovations in preforms and bottle design

The industry of bubble top bottles is a leader in the innovative use of materials and technology for packaging products. A recent development in the field is the emergence of new manufacturing technologies for plastic bottle preforms.

1. Smart preforms

The type of preform used to manufacture plastic bottles in the future may include embedded electronic tracers or QR codes, which enable complete tracking of the bottle from the point of manufacture to the point of recycling. By utilising smart preforms, manufacturers will be able to track where the bottle was manufactured, when it was manufactured, and where it was shipped.

2. Advanced lightweighting

Technologies that enable manufacturers to create plastic bottles that are even lighter while still being able to resist breaking are being developed. These emerging technologies will enable manufacturers to produce lighter bottles (while still having the same strength), reducing resin usage and the carbon footprint of a bottle.

3. Hybrid material preforms

Current research is being conducted on the use of bio-based materials to make bottles that are both durable and environmentally friendly by using PET and bio-based materials together.

4. Enhanced multi-layer preforms

Multi-layer preforms are made with two or more layers of resin, which increases the barrier protection against oxygen, thereby extending the shelf life of products other than water.

5. Fully circular rPET adoption

With the development of better recycling systems, you will likely see an increase in the use of preforms made from 100% recycled PET without sacrificing the quality of the preform.

Final thoughts

While on the surface a bubble-top bottle appears to be an uninspired container for water, the ability of a bubble-top bottle to hold water, or other liquids, is determined far in advance of the time it is purchased by a consumer. The success of a bubble top bottle is attributed primarily to the so-called preform, which represents a minor component of the overall packaging but bears a great deal of responsibility for the ultimate performance and durability of the bubble top bottle.

A business that understands the different types of preforms available for plastics can take advantage of several key benefits:

- The ability to maintain consistency in the strength and quality of the plastic.

- The ability to lower production costs through the use of optimally light-weight preform materials.

- The ability to promote sustainability through the use of preforms produced using recycled or advanced materials.

- The ability to stay ahead of changing trends by using innovative designs for preforms.

Competitively intelligent brands recognise that the quality of a bottle is directly linked to the quality of the preform. Therefore, selecting the best partner for your bubble top plastic preform supply is critical to the success of your brand, product, and profitability.

DRJ Plasttech supports businesses in realising these advantages by providing the best quality preforms specifically engineered for the production of bubble top bottling applications. The combination of advanced manufacturing techniques, rigorous quality control, and a focus on meeting customer needs ensures that every preform produced becomes a finished product, which meets or exceeds your expectations.

So, the next time you reach for a bubble top bottle, take a moment to reminisce on its journey to the shelf and realise that it started with a preform.

FAQs on Bubble Top Bottles and Preforms

1. What is a Bubble Top Bottle, and where is it used?

A bubble top bottle is an extra-large capacity PET (PolyEthylene Terephthalate) container generally holding between 15 to 20 litres of liquid. These bottles are most commonly utilised for water dispensers in places like homes, offices, and gyms. These bottles are designed to be very durable and will last through numerous cycles of use.

2. Why is the Prefabrication Process Important When Making Bubble Top Bottles?

The prefabrication process determines the clarity, strength, and balance of the overall bottle. If the preform used to create the bottle is not manufactured properly, it could cause weak bottles, excessive leakage, or increased production rejections.

3. What Types of Prefabricated Bottles are Used to Make Bubble Top Bottles?

The most common types of prefabricated bottles used to manufacture bubble top bottles include standard PET preforms, heavy-duty preforms, light-weight preforms, recycled PET preforms (rPET), and specialty preforms for custom designs.

4. How Does Preform Weight Affect The Overall Quality of a Bubble Top Bottle?

If the preform used to manufacture the plastic bottle is lighter than recommended, the resulting manufactured bubble top bottle may collapse or shatter during the filling process. On the other hand, if the preform is heavier than necessary, it will create unnecessary production costs. Therefore, developing an optimal weight of a preform will allow for the proper strength of the bubble top bottle without excessive waste.

5. Recycled PET Preforms – Are they Appropriate for Bubble Top Bottles?

Yes. Recycled PET Preform Types (rPET) have become popular as an alternative for use in the manufacture of bubble top bottles. Because of the sustainability benefits associated with using rPET preforms when sourced from reputable suppliers, rPET preforms provide brands with an environmentally friendly option that maintains clarity and durability.

6. Is it Possible to Customize Bubble Top Bottles by choosing the Right Plastic Bottle Preform?

Certainly. Many companies are using different plastic bottle preform types to create customised neck finishes, colours, and even embossed logos to strengthen their brand recognition on the products that they sell in bubble top bottles.

7. What Design Trends are Influencing the Bubble Top Bottle Market?

Here are some of the current design trends that have influenced the market for bubble top bottles: Lightweighting, Ergonomics (comfortable grip), rPET, Durable Multi-use Bottles, and Aesthetics (tinted or embossed finishes).

8. How Do You Find a Supplier to Purchase Your Plastic Preforms?

When sourcing your plastic preforms used to manufacture bubble top bottles, it is important to research potential suppliers in order to find one that uses state-of-the-art technology, performs comprehensive quality checks, offers customisation options, and has a dependable delivery schedule.

9. What should companies consider when selecting a plastic preform type?

Most frequently, customers make the mistake of selecting a preform based solely on its price; they don’t consider weight optimisation, they don’t consider the sustainability factor, or they don’t consider the proper mould design to match the bubble top bottle.

10. What innovations are expected with respect to plastic preform types for use in bubble top bottles?

The future of plastic preform types may include fully circular rPET preforms, new lightweight designs, multi-layer (or multiple) preforms used to extend shelf life, and smart preforms which contain traceable features.