The modern-day packaging market is competitive, fast-paced, and a matter of cents. For a beverage manufacturer, an FMCG supplier, or a manufacturer of consumer goods, the costs associated with packaging can determine whether or not their business is profitable. The main source of those costs is typically the production of plastic PET preforms.

The majority of companies historically manufactured preforms in-house to ensure an adequate supply of product and control over their quality. However, many companies are beginning to shift their mindset away from the “do-it-yourself” model of PET preform manufacturing, to opting to outsource that function to a specialized supplier — and enjoying the benefits associated with that shift.

In this blog post, I will provide insights on why outsourcing is not simply a way to save money, but instead is a way for brands to position themselves for future success, grow their businesses, improve quality, and remain competitive.

Table of Contents

- Why preforms matter in packaging

- The rise of outsourcing in the packaging industry

- Hidden benefits of outsourcing PET preforms

- Why plastic bottle manufacturers are embracing outsourcing

- What to look for in a reliable outsourcing partner

- Common misconceptions about outsourcing preforms

- Final thoughts

- FAQs on Outsourcing PET Preforms

Why preforms matter in packaging

For a bottle manufacturer or brand based on bottles, preforms have direct implications for:

- The strength and durability of the product: A properly-formed plastic bottle resists deformation throughout its lifetime.

- The branding of products: Clear, consistent, and shiny finishes are significant factors in how consumers view bottled products and companies.

- Operational efficiencies for bottling Lines: Bottle lines function better with properly formed preforms.

- Financial management of production costs: The savings achievable by reducing preform weight, no matter how small, can reach several lakhs of rupees each year.

For these reasons, many companies are reevaluating whether they should handle their own preform production or outsource to a company specializing in plastic bottle production.

The rise of outsourcing in the packaging industry

Outsourcing packaging isn’t something that’s new. Companies have been doing this for some time by outsourcing their logistics, warehousing, and raw materials. Recently, companies have started to outsource the manufacturing of plastic PET preforms.

Why have companies decided to outsource their Preforms? It takes a significant investment in equipment, machinery, molds, skilled labor, and quality control systems to manufacture the preforms. For many brands, this is not their expertise; therefore, they rely on the capabilities of a manufacturer that specializes in the production of preforms.

Through outsourcing the manufacturing of Preforms, they can reduce risk, optimize the supply chain, and utilize their capital in areas where they receive the highest return.

5 Hidden benefits of outsourcing PET preforms

Most companies think about reducing their costs when outsourcing a service. However, the main benefit from outsourcing comes from the benefits received that may not be seen immediately as cost savings.

1. Reduced capital expenditure

Establishing an Internal production site for the production of plastic injection-molded (i.e., PET) preforms is capital-intensive (i.e., millions in capital investment). These costs include the cost of new, high-precision injection molding machines, the cost of new molds for plastic preforms of various neck sizes, the cost of utilities, and the cost of ongoing maintenance.

When brands outsource their plastic preform production, they do not have to incur the above costs, and their capital can be used for either R&D or expansion into new markets.

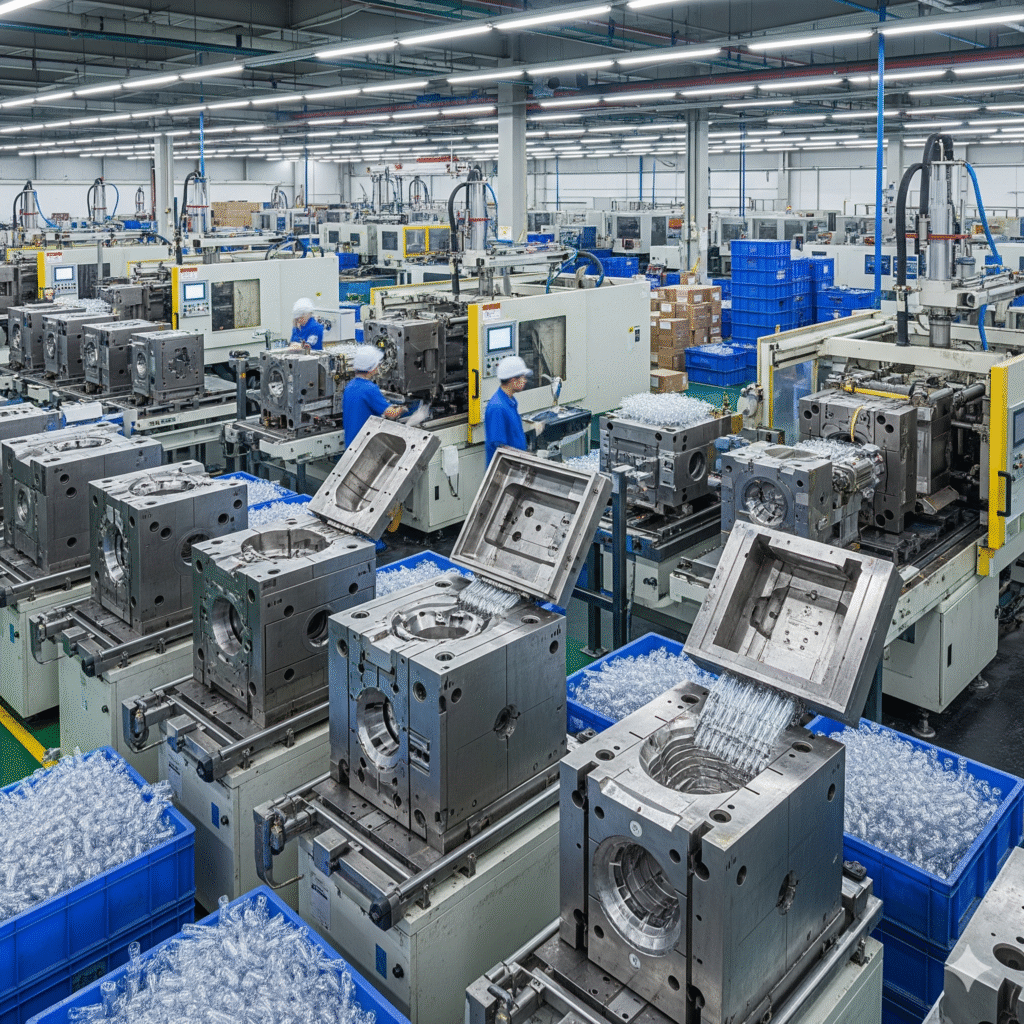

2. Access to expert technology

In general, specialized suppliers (i.e., plastic bottle manufacturers) invest heavily in advanced injection molding and automation technologies. The outsourcing option allows companies access to these advancements without the investment needed to purchase or maintain this complex, high-quality equipment.

For example, specialized plastic bottle manufacturers produce:

- High-cavitation molds to accommodate high-volume production.

- Real-time monitoring systems to ensure consistent weight and dimensions.

- Multi-layered preforms for improved shelf-life and sustainability.

As a result, these technical advancements help with improved quality for plastic bottle manufacturers, but these manufacturers do not have to bear the additional financial cost to upgrade their existing technologies.

3. Improved consistency and quality control

Consistency throughout the millions of preforms manufactured in-house is one of the largest challenges faced by a preform producer. Even the smallest discrepancies can stop production prematurely and lead to unacceptable conditions at either the appliance or packing line.

There are benefits to outsourcing the production of plastic bottles to a manufacturer who provides a constant flow of plastic bottle-grade resins with:

- Standardised quality checks for each batch.

- A history of producing error-free batches at all levels.

The result is less hassle for those within purchasing departments, as well as less disruption during the production cycle.

4. Better supply chain efficiency

When a company produces its own resin grades, it takes on the additional responsibilities and risks of labour shortages, machine downtime, or limitations in access to resin supplies.

By outsourcing, none of these responsibilities or risks is transferred to the producer. An established outsourced producer will have the production capacity, redundancy, and logistics capabilities that are needed to provide uninterrupted resin supplies. An outsourced production partner will, therefore, be able to:

- Reduce the need for large resin inventories.

- Provide on-time production of resin or preforms.

- Be able to respond quickly to spikes in demand.

Outsourcing allows plastic bottle manufacturers to minimise production bottlenecks and increase flexibility.

5. Cost savings through economies of scale

The volumes of plastic PET produced by specialist plastic bottle manufacturers typically exceed 1,000 tons per year. Because of this, these companies can negotiate lower resin costs and operate their machinery much more effectively than smaller manufacturers, and also can spread their overhead costs over a larger volume of products.

Brands that outsource their plastic PET preform production to these manufacturers gain access to the economies of scale that larger manufacturers can achieve with their larger-scale operations; the costs associated with having in-house operations would likely be impossible to attain for smaller manufacturers.

Why plastic bottle manufacturers are embracing outsourcing

Interestingly, outsourcing isn’t just a strategy for brands — even some plastic bottle manufacturers themselves outsource It is interesting to note that brand owners are not the only ones using outsourcing; plastic bottle manufacturers also outsource preform manufacturing. By partnering with a specialized manufacturer of plastic PET preforms, the manufacturer can reduce the high shipping costs associated with this supply chain and instead concentrate on their blow-molding operations.

With this strategy, manufacturers can:

- Eliminate expensive equipment investment.

- Create more floor space for bottle manufacturing.

- Speed up production by only focusing on their core competencies.

As a result, the supply chain will become a more streamlined and efficient network whereby each supply chain segment is performed by a specialist.

What to look for in a reliable outsourcing partner

Finding a good partner to outsource production to is essential for success. Not all plastic bottle manufacturers and preform distributors provide the same quality, production capacity, or levels of service. When evaluating potential suppliers, several factors must be assessed:

- Production Capacity: Is the supplier capable of servicing customers’ needs for both a steady and seasonal production demand?

- Customization: Is there flexibility in the production process, such as in the weight, color, and neck-width of the bottles?

- Technology: Does the supplier employ modern, automated technologies to ensure accuracy in the production of the products?

- Quality Assurance: Does the supplier have an established system in place to ensure that every batch produced is consistently checked for quality?

- Sustainability Practices: What are some of the ways that they are incorporating recyclable materials into their manufacturing process and/or reducing their overall energy usage?

- Location and Logistics: By locating closer to a bottling plant, transportation costs and lead times can be minimized.

The true value of outsourcing comes when there is a reliable and trustworthy supplier who can fill the role of a long-term business partner.

Common misconceptions about outsourcing preforms

Outsourcing is a significant change, and like most major changes, it carries its share of myths and concerns. Below are several common misconceptions regarding outsourcing that are not supported by the facts:

“Outsourcing means losing control.”

Incorrect. When buyers establish clear specifications and quality standards and properly document that information, they typically end up with more control through their process.

“It’s only for big brands.”

Incorrect. Smaller organizations and start-up businesses tend to experience greater advantages from outsourcing since outsourcing allows businesses to avoid the costs associated with large upfront investments.

“Outsourcing compromises quality.”

Incorrect. Outsourcing has the potential to improve product quality through access to superior technology and the more stringent quality control measures available from many specialized manufacturers.

“It’s always more expensive in the long run.”

Incorrect. When taking into account the costs associated with operating your own facility, such as maintenance, labor, sourcing of resin, and downtime, outsourcing is typically a much cheaper option.

Final thoughts

Outsourcing PET Preform Production is more than just saving money; it’s about allowing the smartest brands to concentrate on what they do best by delegating the complexities of Preform Manufacturing to professionals.

There are many hidden benefits to this process.

- Do not require a large upfront investment for capital equipment.

- Gain access to state-of-the-art technology.

- Consistent production quality with fewer defects.

- Reliable supply chain.

- Reduced overall costs due to economies of scale.

Whether you are an emerging or an established business, partnering with a reputable supplier of PET bottles or a dedicated PET Preform Supplier provides unique opportunities for long-term success.

At DRJ Plasttech, we partner with PET manufacturers and brand owners in the state of Gujarat and throughout India to produce high-quality PET Preforms that meet the exact specifications of our customers. By outsourcing your Preform needs to DRJ, you can save money, reduce your total production costs, improve your quality, and increase your production capability without incurring the overhead costs associated with maintaining an in-house production line.

When you evaluate your packaging strategy, ask yourself, “Am I spending too much time and money managing the production of Preforms?” The best brands have already figured this out and are outsourcing their manufacturing requirements.

FAQs on Outsourcing PET Preforms

1. Describe a plastic PET preform and explain its significance for packaging.

The injection-molded part that is subsequently blow-molded into bottles or other containers is called a plastic PET preform. The final packaging’s durability, appearance, and cost-effectiveness are all directly impacted by its design, weight, and quality.

2. Why should a manufacturer of plastic bottles think about outsourcing PET preforms?

Outsourcing helps a plastic bottle company by lowering capital expenditures, avoiding equipment maintenance, and gaining access to cutting-edge preform technology. This enables them to concentrate more on customer service and bottle production.

3. How can manufacturers cut expenses by outsourcing PET preforms?

A plastic bottle manufacturer can avoid expenses associated with injection molding equipment, molds, skilled labor, and energy consumption by outsourcing. Additionally, they profit from the economies of scale that a specialized preform supplier can attain.

4. Are big plastic bottle companies the only ones that outsource PET preforms?

No. Outsourcing has advantages for both big producers and small startups. In particular, smaller plastic bottle manufacturers can access premium plastic PET preforms while saving money up front.

5. How does a manufacturer of plastic bottles guarantee quality when PET preforms are outsourced?

Reputable vendors employ stringent quality controls, standardized procedures, and cutting-edge injection molding technology. For assurance, a lot of suppliers of plastic PET preform also offer comprehensive specifications and certifications.

6. What dangers come with contracting out plastic PET preforms?

Logistics delays and supplier dependability are the primary risks. However, these risks are reduced by selecting a seasoned plastic bottle manufacturer or preform supplier with robust capacity and quality systems.

7. Can supply chain efficiency be increased by outsourcing plastic PET preforms?

Indeed. Because suppliers typically have greater production capacity, a plastic bottle company that outsources preforms can minimise downtime, maintain a steady inventory, and react swiftly to demand spikes.

8. Do customisation requirements get met by outsourced plastic PET preforms?

Of course. Expert plastic bottle producers enable brands to have packaging that meets their needs by offering customisation in neck sizes, weights, colours, and resin grades.

9. Is it more sustainable to outsource PET preforms than to produce them internally?

Yes, most of the time. Compared to smaller, less effective setups, outsourced plastic PET preforms are more environmentally friendly because large-scale plastic bottle manufacturers invest in energy-efficient machinery and recycled PET integration.

10. How can I pick the best vendor to outsource plastic PET preforms?

Seek out a partner with robust capacity, dependable delivery, customisable options, and proven quality systems. Long-term cost savings and consistent quality can be guaranteed by a reputable plastic bottle manufacturer like DRJ Plasttech.