Many businesses that produce or package bottled water may feel extremely enticed to invest in a machine that produces PET preforms (the container-style items made out of polyethylene terephthalate). Having your own ability to produce preforms means you have complete control over your customised preform designs and can produce them on demand. However, does the benefit of owning this equipment outweigh the cost?

At DRJ Plasttech (as a leader in Gujarati companies producing and supplying PET preforms), we can provide both sides of the argument, accurately advising our customers on whether or not they should invest based on their unique production requirements.

This article will discuss some of the best available investment options for new and existing businesses, assess potential investments as a possible waste of money, and suggest better options that provide less financial risk while allowing you to achieve your production objectives.

Table of Contents

Understanding the Real Cost of a PET Preform Machine

5 Operational Challenges with In-House Machines

When Buying a PET Preform Machine Is Worth It

Smarter Alternatives to Buying a PET Preform Machine

The Financial Math: Total Cost of Ownership

Long-Term Strategy: Scaling Without Overextending

Why DRJ Plasttech is a Smarter Alternative

Final Verdict: Outsourcing or Buying — What’s Right for You?

Smarter Growth Starts with Smarter Partnerships

FAQs: Buying PET Preform Machinery

Understanding the Real Cost of a PET Preform Machine

You should be aware of what is included in your investment into a pet perform machine (and its associated costs) before you make a substantial investment into this organization, as this kind of machine is part of a larger ecosystem that requires space, trained employees, maintenance of equipment, and a consistent source of raw materials for production. A pet perform machine is not just an individual purchase – it contains a great deal of other areas within your company that will be affected.

The Machine Itself

A fully operational, premium-quality preform pet bottle production machine might run anywhere from ₹20 Lakh – ₹1 crore+, depending upon capacity and technology used.

The average prices of pet performance machines in the Indian market:

- Small-scale (up to 150 tons): ₹25 – ₹45 lakh

- Mid-scale (150 – 250 tons): ₹45 – ₹70 lakh

- High-volume (more than 250 tons): ₹70 lakh – ₹1.2 crore, or greater.

This figure does not include shipping, installation, or the cost of moulds.sts.

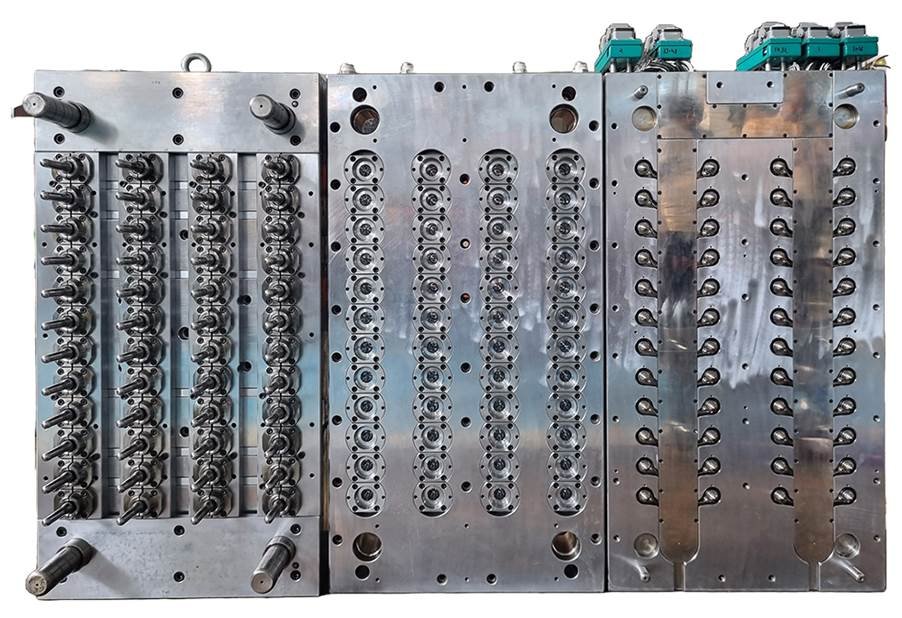

Custom Moulds & Tooling

All PET preform machines will use different molds for their bottles; therefore, depending on the design of your mold, your fabrication costs will vary between ₹5 lacs and ₹15 lacs for each format.

If you have multiple neck finishes, you will also need to factor in ₹10 lacs to ₹20 lacs extra to your budget for that.

Infrastructure & Setup

Along with your preform line, you will also have additional items to help you with your operation:

- Climate-controlled storage for PET resin.

- Electricity supply with several hundred volts of electricity.

- A supply of compressed air and a supply of coolant/chilled water.

- Trained personnel to operate and maintain your machinery.

These additional items will be an estimated cost of ₹10 lacs to ₹25 lacs more than initially planned for the setup of your preform line.

5 Operational Challenges with In-House Machines

The learning process continues after you become operational. In reality, the complexities of running a high-volume PET bottle manufacturing plant are frequently miscalculated by organizations.

1. It’s Hard to Find Skilled Work

PET facilities don’t use the “plug and play” methodology when operating machines. These facilities hire skilled employees who possess a list of attributes:

- The appropriate temperature range for melting PET and the viscosity of the polymer

- Cycle times, ability to maintain machine calibration, and how to assess quality

Skilled workers are relatively costly and rare within the labour market.

2. Downtime is Inevitable

All machinery has mechanical/technical faults, whether planned or unplanned. Even when utilizing the most reliable machinery with regular maintenance, unanticipated downtime may occur due to:

- Utilizing unexpected time which is not accounted for on the production schedule

- Disrupting the deliveries to your customers, and

- Costly sales losses due to maintaining inventory, which can never be recovered

High volume PET bottle manufacturers encounter both negative impacts on their profitability, along with a loss of reputation in the business-to-consumer environment, as a direct result of prolonged and frequent equipment downtimes, particularly for customers with rapid delivery requirements.

3. Resin Waste is a Cost Drain

New operators will often produce excess amounts of PET Waste during the initial setup phase of new machines due to improper calibration, overheating or underheating parts, and short-shot production. Each of these variables creates excessive amounts of waste, which, depending on the price of resin, could result in several thousands of dollar/month losses for your organization.

4. Quality Control and Risk Management

Quality control may be the most significant distinction between producing your own preforms and outsourcing to professionals like DRJ Plasttech.

5. Inconsistent Quality from Inexperienced Teams

It’s challenging to consistently produce preforms with the proper weight, transparency, strength, and finish. Small variations in melt temperature or moisture content can result in:

- Necks that break easily

- Dimensional mistakes

- Defects and blush marks

When Buying a PET Preform Machine Is Worth It

We are not here to dissuade you from using your own resources to manufacture products. There are times when purchasing a pet preform machine is a good decision based on the following reasons:

- You have a consistently high volume demand for products

- You have a guaranteed long-term source of resin

- You have sufficient facilities and trained personnel

- You need to maintain complete control of the design of proprietary bottles

- The cost per unit from outsourcing is too high for your volume

In these instances, investing in a preform pet bottle machine has the potential to be very lucrative in the long term, provided you have a definitive growth strategy and the technical expertise to implement it properly.

When It’s Not Worth It

The statements may coincide with your current situation, and therefore, you should think twice before making a machinery purchase.

- You have a seasonal or inconsistent demand for products

- You cannot afford technical personnel on a full-time basis

- Your money may be better spent on marketing, distribution, or ready to bottle

- You have little knowledge about how to obtain resin or perform QA on resins

In these cases, working with a company like DRJ Plasttech that you can rely on is a much better option.

Smarter Alternatives to Buying a PET Preform Machine

Now for the smarter path: outsourcing strategically while maintaining control over your packaging supply chain.

At DRJ Plasttech, we provide flexible PET preform supply solutions that fit your unique business needs.

Volume-Based Pricing

We manufacture more than 15 tons of PET preforms each day; therefore, our pricing structure is significantly lower than the prices charged by smaller in-house operations when considering price per kg on bulk orders. Customers ordering bulk quantities will also benefit from larger quantity discounts and convenient delivery schedules.

Preform Customisation (Without Machinery Investment)

We’re here to help you develop molds for custom neck finishes and branded preforms that meet your exact specifications, so you can achieve your unique packaging style without investing in your own moulding equipment.

Quality Guarantee, Always

All of our preforms are backed by a 100% quality assurance guarantee, ensuring that you have trouble-free production of your bottles on your blow moulding equipment. Zero defects, zero returned caps.

The Financial Math: Total Cost of Ownership

To assist in making an educated decision, we will begin by evaluating the total cost of core possession for a PET preform machine over five years compared to outsourcing production to a manufacturer like DRJ Plasttech that focuses on PET preforms.

Scenario A: In-House PET Preform Manufacturing

| Item | Estimated Cost (INR) |

| PET Preform Machine | ₹60,00,000 |

| Mold Setup (2 sizes) | ₹15,00,000 |

| Infrastructure Setup | ₹20,00,000 |

| Skilled Labor (5 years) | ₹30,00,000 |

| Maintenance & Parts | ₹7,00,000 |

| Resin Wastage Loss (avg. 3%) | ₹10,00,000 |

| Total | ₹1,42,00,000 |

The numbers show that even for relatively low-volume production, the total cost of ownership is considerably more than ₹1.4 crores. The total cost of production does not include interest payments or loan repayments on the purchase of the PET preform machines. This analysis assumes that all of your equipment will run with no downtime.

Scenario B: Outsourcing to DRJ Plasttech

| Item | Estimated Cost (INR) |

| Preform Purchases (₹85/kg avg.) | ₹85,00,000 (over 5 years) |

| Transport & Logistics | ₹2,00,000 |

| Quality Control & Returns | ₹0 (covered by DRJ) |

| Machine Downtime | ₹0 |

| Maintenance | ₹0 |

| Total | ₹87,00,000 |

When you outsource to DRJ Plasttech, you have reduced your total capital investment by almost ₹55 lakhs. You have also eliminated the challenges of managing complex manufacturing operations.

Long-Term Strategy: Scaling Without Overextending

Many click-and-mortar bottlers have identified scalability without overextension as a potential means for sustainable business growth. Despite the appealing aspect of manufacturing PET preforms in-house, bottlers will likely encounter the following bottlenecks down the road:

- Unanticipated capital expenses

- Inefficient supply chains

- Operational interruptions

A true partnership with a complete, full-service preform supplier allows bottling companies to:

- Expand into new geographic markets quickly

- Manage production volume by season

- Concentrate on sales, branding, and distribution

- Direct growth efforts toward increasing sales to consumers rather than investing resources into the production side of the business

DRJ Plasttech can provide custom-tailored supply chains for both established brands seeking to develop a strong photo value proposition in the market, as well as for businesses looking to provide additional retail sales opportunities in a key part of their retail sector as an important capital supplier.

Why DRJ Plasttech is a Smarter Alternative

We manufacture PET Preforms and provide you with a strategic extension for success.

A. Capacity You Can Count On

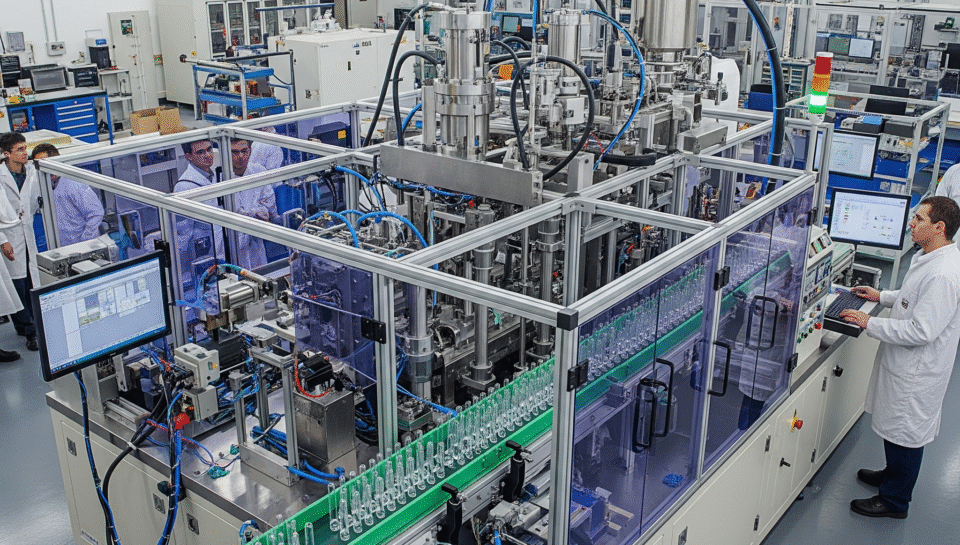

Our 40,000 sq. ft facility, with a capacity to produce 15+ tons of PET preforms daily (no delays, no matter the busy season).

B. Consistency You Can Trust

Rigorous quality assurance practices provide:

- No risk of contamination

- Constant wall thickness

- Exact weights and dimensions

- Compatible with all blow moulding systems

You will never have to worry about inconsistent batches of product that ultimately affect the quality of your final bottled product or trial runs.

C. Competitive Pricing Structure

Due to our economies of scale and transparent pricing strategy, we offer very competitive rates on PET preforms based on kg in India, without compromising material quality and performance.

Our pricing strategy is optimized for value, reliability and repeatability, whether you order 5 tons or 500 kg.

D. Innovation for Future Growth

We continually seek new product lines and packaging solutions to meet the changing needs of the packaging industry, from lightweighting to eco-friendly resin compatibility.

Final Verdict: Outsourcing or Buying — What’s Right for You?

Here’s how to decide:

| Factor | In-House | Outsourcing |

| Capital Availability | High Required | Low |

| Volume Consistency | Required | Flexible |

| Technical Expertise | Essential | Not Required |

| Time to Market | Slower | Faster |

| Operational Risk | High | Minimal |

| Scalability | Fixed | Adaptive |

| Focus | Manufacturing | Sales & Growth |

In-house PET preform manufacturing only makes sense if:

- Large companies that have a stable volume of production

- Owners who have sufficient resources and the expertise to manufacture preforms

- Companies that want full control of the packaging process

Outsourcing to DRJ Plasttech is the right choice if:

- Begin methodically growing their manufacturing operations instead of attempting rapid growth.

- Minimize the financial risks associated with capital investment

- Maintain both flexibility and a reliable supply chain

Smarter Growth Starts with Smarter Partnerships

At DRJ Plasttech, we aim to provide simplified supply chain solutions for all our clients. We not only offer quality PET preforms, but we also make it easy for our customers to grow their business.

Because we create production schedules that are tailored to our customers’ needs and have a logistics system in place to handle all logistical tasks, including delivery and warehousing, we help our customers achieve their desired growth and profitability. This enables our customers to grow their brand, achieve economies of scale and lower costs.

If you are still undecided on purchasing a PET preform machine or outsourcing your PET preform production, we are happy to assist you with an ROI analysis for your specific needs.

We could talk about numbers, the potential of your investment and eliminating the uncertainty in determining which route will be best for the future of your business.

FAQs: Buying PET Preform Machinery

1. What is the purpose of a PET preform machine?

The initial form of PET bottles, known as preforms, is produced by an injection molding process using a PET preform machine. Afterwards, these are blow-molded into completed bottles.

2. How much does an average PET preform manufacturing machine cost in India?

Depending on the brand, tonnage, cavity count, and automation features, the price can vary from ₹35 lakhs to more than ₹1 crore.

3. Is it less expensive to outsource production or purchase a preform PET bottle machine?

Your scale will determine this. For small to mid-sized businesses, outsourcing is frequently more economical because it eliminates the need for expensive initial capital, labor, and upkeep.

4. What elements influence the price of PET preform machines?

Machine tonnage, cavity size, mold design, degree of automation, energy efficiency, and post-purchase assistance are important variables.

5. Can I use a single machine to begin PET preform production?

Yes, but it’s crucial to take into account a steady supply of raw materials, technical personnel, maintenance capabilities, and operational space.

6. How long does a PET preform machine last?

A PET preform machine can last 10 to 15 years with routine maintenance, but over time, productivity and energy efficiency may decrease.

7. Does operating a PET preform machinery come with hidden costs?

Yes, including cooling systems, electricity, skilled labour, mould maintenance, and possible downtime from technical problems.

8. What are better options than purchasing PET preform machines?

Consistent quality, less operational complexity, and lower overall costs are guaranteed when working with a reputable manufacturer like DRJ Plasttech.

9. Does India have easy access to local machine servicing?

The manufacturer determines whether services are available. Imported machinery can result in longer wait times and higher costs, even though top brands provide local support.

10. What makes DRJ Plasttech a better option than purchasing equipment?

We help businesses concentrate on growth rather than machinery headaches by providing scalable supply, unparalleled quality control, and flexible ordering without the significant capital investment.