Outsourcing PET preforms or manufacturing them internally is one of the most controversial questions in the fast-paced world of packaging. On the surface, producing your own preforms seems like it may be a beneficial long-term decision financially. However, when you factor in costs associated with raw materials, machine maintenance, equipment purchase costs, labour costs, and energy consumption, it is a completely different calculation.

We will compare these options in terms of costs, risks, benefits and long-term effects to help you decide which option best serves your financial interests while enabling you to produce high-quality/preferred preforms at ultimately low cost while maintaining quality and consistency.

Table of Contents

Understanding the Real Costs of Manufacturing PET Preforms In-House

The Case for Outsourcing PET Preforms to a Trusted Partner

Comparing PET Price in India: In-House vs. Outsourced

Beyond Cost: Strategic Benefits You May Be Overlooking

So, Is Outsourcing a Complete Waste of Money? Absolutely Not.

FAQs on Outsourcing PET Preforms vs. Manufacturing In-house

Understanding the Real Costs of Manufacturing PET Preforms In-House

The majority of businesses grossly miscalculate their actual production costs to produce their own PET preforms, largely because they fail to factor in a myriad of variables. Below are some examples of the variables:

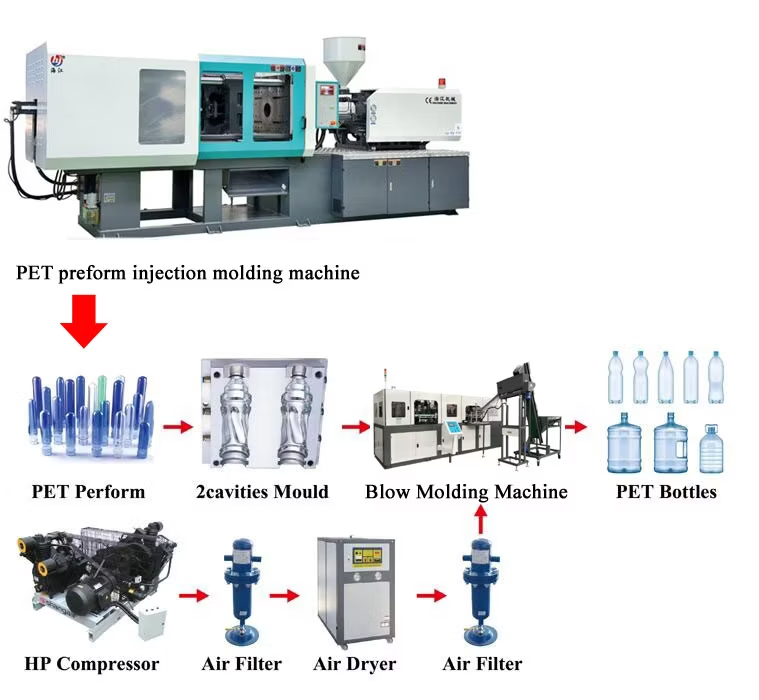

1. Machinery Investment: A Massive Upfront Cost

When you decide that you want to manufacture your own PET preforms, you will first need to invest in high-precision injection moulding machines, sets of moulds to make different sizes of preforms, chillers, dryers, and controllers to maintain the temperature of the moulds. The price of a high-quality injection machine ranges from ₹60 lakh to ₹1.5 crore, depending on the size of the machine and its features.

The return on investment will typically take three to five years, assuming that you have a consistent flow of production and have very little downtime on the machine.

2. Tooling & Mould Costs

The moulds are the most critical component of your PET preform production operation. Every mould (28 mm neck, 30 mm neck, etc.) costs ₹10 lakh – ₹25 lakh to manufacture and is specifically designed for your preform production process. Wear-and-tear on your moulds will require you to service them regularly or replace them, which adds expense to your operating costs each year.

3. Trained Manpower and Maintenance

Creating PET bottle preforms requires an experienced team to oversee injection molding operations, troubleshoot production problems, maintain equipment, and perform quality inspections. This will require salaries for additional support personnel and expenses related to training this type of employee.

4. Power Consumption

Injection molding uses a significant amount of electricity. Each month, electric bills from injection-molding machines can reach hundreds of thousands of rupees, depending on machine size and the total number of preforms produced. Intermittent power supply disruptions can also affect product uniformity and lead to machine shutdowns when power supplies are unreliable in certain countries/regions.

5. Raw Material Procurement and Storage

Purchasing virgin or recycled food-grade PET resin can create an immediate cash flow issue. The volatility of raw materials prices creates additional financial risk to your profits. You will also have to invest in creating a humidity-controlled environment for your resin before using it to help prevent contamination or degradation, thus incurred additional costs.

Tip: The cost for PET preform production (price/kg) is strongly correlated with fluctuations of crude oil prices, availability of resin, and shipping methods. Outsourcing the production of PET preforms provides you with fixed or contractual rates that are insulated from these variations.

6. Quality Control & Consistency

When businesses without prior experience in manufacturing plastic products start to make products in-house, there is often a huge level of variation that may occur due to a lack of experience. If there is any irregularity in wall thickness/size, flash on preform products, or any ovality found in preform products, this can harm the downstream process of sealing preform containers and may cause the entire downstream process of filling, transporting, and sealing product through automated operations to become less effective, resulting in rejected products, increased delays, and increased customer complaints.

The Case for Outsourcing PET Preforms to a Trusted Partner

Reasons to use trusted suppliers/expert manufacturers when outsourcing PET preform needs

1. Zero Capital Investment

When you outsource, there’s no need for you to purchase machinery, moulds, or hire employees to do the manufacturing of PET preforms. You can convert this fixed capital expense into a variable cost. You pay only for what you need when you need it.

This is especially advantageous for:

- Start-up or small bottling operations

- Businesses that operate seasonally and require a product that fluctuates in demand

- Organizations that wish to concentrate on their core business operations (i.e., bottling/distribution)

2. Predictable Pricing: Know Your Margins

Partnering with a manufacturer such as DRJ Plasttech gives you complete transparency and predictability regarding your costs. Whether you order 10,000 or 1,000,000 preforms every month, you will benefit from pre-negotiated pricing that has been determined based on volume, resin type and neck size.

This is why the terms PET bottle preform price or PET preform price per kg have relevance. Instead of having to monitor the daily fluctuations of the PET resin market, you can lock in your supply of preforms at a fixed price for preforms in India, thereby enabling better budget and inventory management.

3. Superior Quality and Consistency

Manufacturers with a track record of excellence typically utilize advanced injection machines, robotics, and in-line QC systems to guarantee that each preform produced meets the weight, neck dimension and clarity tolerances set forth by the industry. As a result of implementing this type of quality control, manufacturers experience:

- Fewer Stop Pages on the Bottling Line

- Less Seeping and Capping Failures

- Greater Customer Satisfaction

At DRJ Plasttech, we have stringent quality control procedures in place that ensure all preforms we produce are of the highest possible quality and undergo multiple inspections before being shipped from our facility.

4. Scalability and Flexibility

Need a last-minute batch? Launching a new bottle design? Switching cap sizes?

Outsourcing provides the agility to scale up or pivot product lines without buying new moulds or machines. At DRJ Plasttech, we offer preforms in a wide range of weights, neck types, and colours that are always ready to dispatch across Gujarat and neighbouring states.

5. Time Savings and Business Focus

Instead of worrying about equipment failures, resin shortages, or quality problems, you can concentrate on what you do best, i.e., filling, branding, and selling bottles. A benefit of outsourcing preform manufacturing and logistics is that you will save space in your building by eliminating the need for a moulding area.

Comparing PET Preform Price in India: In-House vs Outsourced

| Cost Element | In-House Production | Outsourcing with DRJ Plasttech |

| Capital Investment | ₹1–2 crore | None |

| Mold Cost | ₹10–25 lakh per mould | Included in unit price |

| PET Resin | Must procure and store | Included in PET bottle preform price |

| Labour & Maintenance | Monthly fixed expense | None |

| Power | High electricity usage | None |

| Quality Control | Internal burden | Handled by DRJ’s QA team |

| Turnaround Time | May vary | Guaranteed timelines |

| Customisation | Limited by in-house tooling | Wide selection available |

| Scalability | Dependent on capacity | Easily scalable |

| Average PET preform price per kg | ~₹120–₹150 (raw + overhead) | Fixed competitive rates |

Beyond Cost: Strategic Benefits You May Be Overlooking

When contemplating whether to outsource or produce PET preforms in-house, a manufacturer’s cost analysis is only a fraction of the equation, as the evaluation of factors such as market volatility, speed of entry into the market (time to market), ability to innovate/pivot quickly (innovation agility), and supply chain risk will also play a significant role in the decision.

So let’s explain how outsourcing the manufacturing of PET preform bottles not only saves you money, but also provides you with valuable competitive advantages that are much greater than just cost savings.

1. Time-to-Market: Be First, Be Fast

The beverage and packaging industries are heavily focused on speed! Therefore, if you are launching a new product line or are reacting to quarter or seasonal demand, the importance of getting a product to market first is more critical than ever.

Manufacturing preform bottles in your own facility can cause significant delays due to:

- The set-up time is associated with the production of new moulds

- The numerous testing and quality assurance cycles

- Staff training and schedule changes, which may require creating new shifts or sharing personnel

In contrast, when you utilize a supplier like DRJ Plasttech for your preform bottle manufacturing, you utilize an established facility where pre-existing equipment has already been put in place to produce preform bottles, preform bottle caps, and preform bottle colours. By relying on DRJ Plasttech, you eliminate these production lead times and immediately gain an advantage over your competition by being first to market.for production and delivery. This reduces your lead time drastically, giving your brand a speed advantage over the competition.

2. Market Responsiveness Without Supply Chain Disruption

PET resin is globally traded, and many of its price fluctuations can be attributed to:

- Crude oil pricing

- Import/export tariffs

- Shipping blockages

When using your own facilities to manufacture PET resin, you will directly experience the risks associated with price increases and/or delays related to procuring resin. When the costs or availability of resin increase, it is possible that your entire production schedule will be disrupted.

To ensure our partners are not caught off guard by sudden changes in price or availability, we provide them with a buffer stock of preform components and raw materials. If the market becomes unstable, DRJ absorbs any financial responsibility associated with the changes. As you can see from the historical changes in PET preform pricing in India, outsourcing production allows for the cost of producing PET preforms.

3. Built-In Technical Proficiency

Making PET preforms requires:

- Correct mold temperature

- Accurate injection cycle timing

- Correctly dried and dehumidified resin

- Accurately calibrated neck finish

Even small errors in any of these areas can result in:

- Short shots

- Flash

- Sink marks

- High reject rates

By outsourcing, you are able to tap into the technical expertise of the specialists in this area. At DRJ Plasttech, our team brings together decades of experience in preform moulding, including ongoing training, the use of data to continually upgrade methods, and the use of technology to continuously monitor defects. Consequently, you receive consistent quality and service and fewer headaches in your bottling process.

4. Innovation Without Infrastructure Costs

Do you want to experiment with a new neck size? Are you considering using a lighter preform? Do you want to introduce a new color for a particular season?

To create these products internally, you would need all of the following:

- Invest in a new mold

- Time without production to change to new molds

- Complete multiple testing cycles internally (or buy samples)

Most manufacturing plants would consider this too long an investment for just testing an idea. This is where we are different at DRJ – we think outside the box! We will be able to test various versions of preforms and provide the product by removing all capital overages associated with a test. The benefits of this are:

- Lightweighting for sustainability

- Color-coded preforms for branding

- Specialty resin(s) that are heat- and/or UV-resistant

You have the upside of new product development without having the infrastructure investment.

5. Space Savings = Productivity Gains

Producing preforms requires:

- Space for machines

- Space for storing resin

- Space for cooling structures

- Space for quality assurance

- Space for storing completed products

Outsourcing allows you to free up this area of your facility for more profitable activities, such as bottling, warehousing, or shipping. You will expand your facility’s capacity utilization without increasing your physical footprint and improve your cost-per-unit efficiency dramatically.gains.

6. Reduced Compliance Headaches

PET manufacturing is required to comply with many strict regulations:

- Food Safe Resin Certifications

- Packaging Safety Migration Testing

- Plastic Waste Disposal Properly

- Energy and Emission Compliance

Outsourcing transfers the burden of compliance to the manufacturer as well. DRJ Plasttech meets all BIS regulations; manages resin traceability; and follows eco-compliant procedures so that you can remain audit-ready without stress.

7. Sustainability Goals Made Easier

As businesses work towards becoming more environmentally friendly, choosing where and how to produce PET preforms can affect your company’s EGS initiatives on many levels in producing preforms.

Through outsourcing, you will benefit from:

- Lower amounts of energy consumption,

- Less plastic waste is created while producing preforms,

- The ability to use lighter-weight preforms, resulting in less material usage

- The ability to conduct simplified testing for the presence of rPET content.

By partnering with DRJ Plasttech during your production of PET preforms, you will also have access to a company that has a strong commitment to supporting sustainable business practices. We continually invest in the development of more energy-efficient machines and the production of rPET-compatible moulds that will help you fulfil both your customers’ and regulators’ expectations for sustainability without the need for additional capital investment..

8. Packaging Customisation for Market Differentiation

Increasingly, buyers and retailers expect packaging to be something special that catches people’s eyes from the shelves. A bottle is the first time buyers will have an opportunity to view it.

DRJ Plasttech offers:

- Sizes of the neck (28mm PCO, 30/25, 38mm, etc.)

- Colour-tinted preforms to help differentiate products

- Compatibility with specialty caps

- Matte, clear, and frosted finishes

DRJ Plasttech makes all of this available without requiring you to construct or adapt any existing infrastructure to accommodate these changes. Rarely will in-house manufacturers offer this level of flexibility.

9. Transparent Costing = No Budget Surprises

We’ve worked with dozens of clients who assumed internal production would save money only to encounter hidden costs:

- Tooling errors

- Machine downtime

- Quality rejections

- Unexpected mould maintenance

- Staff retraining

- Lost opportunity due to delays

With DRJ Plasttech, the PET bottle preform price is locked and clear, broken down by size, resin grade, and quantity. That means no budget surprises, no guesswork, just straight numbers you can trust.

10. Volume Discounts at Scale

Are you looking to grow your bottled water or fast-moving consumer goods business? By sourcing costs at higher quantities, you will see a significant increase in your profit margins.

When you work with us, you will have access to:

- Tiered pricing

- Annual supply agreements

- Bulk shipping optimization

- Customized Mould Supports (in accordance with your minimum order quantity)

This will enable you to maintain control over the price of PET Preform per kilo as your business grows, without needing to purchase additional moulds or machines.ying another mould or machine.

So, Is Outsourcing a Complete Waste of Money? Absolutely Not.

Most businesses are better off outsourcing to a company that has established itself as a partner, rather than relying on an in-house solution, especially in cases where a trusted supplier understands their specific customer base, product needs, delivery requirements and industry norms.

When selecting a vendor or supplier for PET Preforms, DRJ Plasttech provides customers with:

- Transparent Price for PET Preforms in India

- Customized Supply Solutions

- Fastest Turn-Around Times in the Industry

- Consistent and Reliable Quality

At DRJ Plasttech, we manufacture up to 15 tons of Pet Preforms per day, using our 40,000 square foot manufacturing facility located in Surat, providing supply services to clients throughout the state of Gujarat and beyond.

If you’re looking for lightweight 28mm PCO Preforms for your bottled water, or heavy-duty Carbonated Beverage Preforms, you’ll consistently get what you need; we produce at scale.

Final Thoughts

Manufacturing PET bottle preforms in-house gives you more control, but it’s also much more expensive, risky, and complicated than outsourcing. If you’re not producing huge amounts of PET bottle preforms, then you will probably make more money and reduce your stress by having the manufacture of your PET bottle preforms done for you.

With so many options available to you, we would love to provide you with a quote for whatever volume of PET bottle preforms you need per unit, per kilogram, or in bulk tonnage. Your success is our priority at DRJ Plasttech.

FAQs on Outsourcing PET Preforms vs. Manufacturing In-house

1. Is it less expensive to outsource PET preforms than to produce them internally?

Indeed, outsourcing is frequently more economical. With competitive PET preform prices per kilogram from seasoned manufacturers, outsourcing production can reduce your overall costs when you account for equipment, personnel, quality control, and downtime.

2. How do suppliers determine the price per kilogram of PET preform?

Resin grade, preform weight, order volume, and customization needs are usually the determining factors. For each PET bottle preform, DRJ Plasttech provides clear pricing so you know exactly what you’re getting.

3. How much does a PET preform cost in India right now?

Depending on market demand and resin costs, prices may change. PET preform currently costs between ₹80 and ₹120 per kilogram in India, depending on specifications.

4. If I outsource my preforms, will I lose quality control?

Not with the appropriate companion. To guarantee that every water bottle produced at DRJ Plasttech satisfies your exact specifications, we adhere to stringent quality standards and carry out batch testing and real-time defect detection.

5. Is outsourcing quicker than producing PET preforms internally?

Of course. Time spent on setup, hiring, and troubleshooting is reduced by outsourcing. Your preform for water bottle needs can be fulfilled with quicker turnaround times thanks to DRJ’s ready moulds and bulk production capabilities.

6. Can the price of PET bottle performance be stabilized over time through outsourcing?

Indeed. DRJ assists clients in locking in pricing, even during market fluctuations, so your PET preform price per kg stays consistent thanks to long-term contracts and dependable supply chains.

7. For outsourcing preforms, what are the minimum order quantities (MOQs)?

Depending on the preform weight and customization, our MOQs change. We provide flexible solutions at competitive PET bottle preform price points to both large and mid-sized manufacturers.

8. If I outsource, do I have to buy molds?

Not always. A variety of standard preform molds are available from DRJ Plasttech. Only specific neck sizes or unique designs—which we can create together—require custom molds.

9. If I outsource to DRJ Plasttech, will I receive a steady supply?

Indeed. At our 40,000 square foot facility, we maintain a consistent resin inventory and production flow. We provide reliable performance for water bottle supply to high-volume customers in Gujarat and surrounding states.

10. Why is DRJ Plasttech the ideal partner for PET preform outsourcing?

We provide:

- India’s top PET performance price

- 15 tons per day is an advanced production capacity.

- Outstanding quality assurance

- A large assortment of preform sizes and types

We are dedicated to becoming your long-term PET packaging partner, not just a supplier.