Precision and consistency have become non-negotiable requirements for successful PET preform manufacturing. The profitability of many companies that use PET bottles to package beverages, oils, or other liquids is reliant on the quality of the preform. As such, a minor pet preform defects could result in significant lost profits due to product rejection, production delays, and unsatisfied customers.

As a leading manufacturer of PET preforms in Gujarat, we at DRJ Plasttech know firsthand how substantial the loss can be from using poor-quality preforms. With over 15 tonnes of premium-quality preforms produced daily from our Surat facility, which spans approximately 40,000 sq ft, we’ve learned that the implementation of consistent quality control will maximize our clients’ profit and reduce costs when compared to those who are still using a non-standard production process.

In this blog, we will discuss seven common defects associated with manufacturing PET preforms, along with ways to correct these issues through proven strategies derived from DRJ Plasttech‘s manufacturing expertise.

Table of Contents

7 Preform Defects Killing Your Profits and How to Fix Them

3. Yellowing or Discolouration

Intermission: Why Quality Control Matters

How DRJ Plasttech Minimises PET Preform Defects

Top 10 FAQs on PET Preform Defects

Ready to Eliminate Defects From Your Supply Chain?

Let’s dive straight into the most common PET preform defects:

1. Preform Black Specks

Cause:

Black specks are caused by the degradation of the resin/base material when making a preform. It can also be caused by leftover material from a prior production run that contaminates the preform when producing a new one. Lastly, small particles of dust or carbonized materials can appear as black specks in the preform.

Impact on Profitability:

The presence of black specks on a preform reduces the consumer’s ability to see through the container; hence, reducing their perceived value. In food or pharmaceutical packaging, any visible black specks result in the entire batch of product being rejected due to the potential for contamination.

Remedy:

- Implement strict hygiene practices when handling raw materials.

- Always use a food grade virgin resins for the production of your containers and preforms.

- Increase the frequency of purging your barrel at the time of product changeovers to reduce contamination.

- Implement filtering/screening devices in the melt flow to capture and prevent materials from entering the preform.

Our specialized systems at DRJ Plasttech take the necessary steps to eliminate black specks before production through advanced cleaning systems combined with quality control measures we have in place to capture contaminants and eliminate their occurrence within our preforms.

2. Bubbles in Preforms

Cause:

The primary cause of bubble formation in preform containers made from PET (also known as Polyethylene Terephthalate) is the moisture content present in the resin before production. The resin’s ability to absorb moisture from the surrounding air (hygroscopicity) creates bubbles when heated or melted during the injection process. Moisture present in the resin will convert to vapour during the injection process, producing bubbles.

Impact on Profitability:

The presence of bubbles in a bottle compromises the strength of the bottle and increases the likelihood of failure during storage and transportation. If your company is producing carbonated beverages, for example, a bottle that contains air bubbles may leak or even break open when being filled or transported, causing expensive rework and excess material waste.

Remedy:

- To prevent bubble formation in preforms, ensure that your PET resin is thoroughly dried prior to production using a dehumidifying drying system. As a general guideline, moisture content should not exceed 0.005%.

- Maintain consistent monitoring of dryer temperature and time duration to prevent under-drying.

- Store PET granules in moisture-tight packaging to prevent mew moisture absorption.

At DRJ Plasttech, we employ sophisticated drying systems that guarantee our preforms are free of bubbles and meet the structural standards required for the highest quality end products.

3. Yellowing or Discolouration

Cause:

Heat build-up during the Injection Moulding Process is the most common cause of Discoloration or Yellowing in the PET Preforms. Other causes may include extended residence times within the injection barrel, or the use of Recycled Materials with excessive levels of impurities.

Impact on Profitability:

The Discoloration of Preforms or their yellowed appearance negatively impacts the overall appeal of your finished Product, especially if they are to be used in clear or lightly tinted packaging. Customers will ultimately reject any Products that do not conform to their colour specifications, and Quality Control inspections may also reject any Product that exhibits evidence of yellowing.

Remedy:

- Ensure that the heating temperatures of the PET Preform are optimised within the ideal heating Temperature Range (generally between 270° C to 290° C, depending on the type of Resin used).

- Minimise prolonged idle times in the injection barrel.

- Utilise High-Quality, Virgin Resin or Well-Sorted Recycled Resin.

- Monitor both your back pressure settings and screw speed during the Injection Moulding Process.

At DRJ Plasttech, we have installed a computer-based Temperature Monitoring system to ensure that each time we produce a batch of PET Preforms, the Heat Profile has been Consistently maintained, thereby reducing the risk of discolouration.

4. Short Shots

Cause:

When the mould cavity is not filled during injection, it creates short shots. This occurs when injection pressure is not adequate, the size of the shot is incorrect, or there are blockages in the runner or gate systems.

Impact on Profitability:

Short shots that are not usable must be discarded, and worse yet, they may be missed before blowing and may result in machine downtime and excess waste.

Remedy:

- Increase injection pressure to allow full filling of the cavity.

- Measure and adjust the size of the shot to match the cavity’s requirements.

- Perform frequent cleaning and inspection of the runners, gates, and nozzles.

- Ensure adequate venting in the mould to avoid trapping of air.

DRJ Plasttech implements a preventative maintenance plan to keep our moulds in the best possible condition to prevent defects like short shots.

Intermission: The Importance of Quality Control

At DRJ Plasttech, we do more than manufacture PET preforms; we create uniformity through engineering. We have inline inspection systems, mould temperature controllers, and accurate dosing systems in our facility to ensure all preforms meet specific customer requirements.

Need preforms that are free from defects consistently? Contact us to learn about how we can help with your packaging needs and to receive a complimentary consultation.

5. Flash at Parting Line

Cause:

During injection, flash happens when extra plastic seeps out between the mold halves. Usually, it is caused by worn mold parts, misaligned molds, or high injection pressure.

Impact on Profitability:

Even tiny flashes require post-processing or trimming, which increases labor and expenses. Bottle leaks or capping problems may result from inconsistent flash removal, which can harm preform necks.

Remedy:

- To guarantee precise alignment and seal integrity, molds should be routinely inspected and maintained.

- Without sacrificing fill, lower the injection pressure to ideal levels.

- To reduce separation, make sure the right amount of mold clamping force is used.

To reduce the possibility of flash and guarantee that every preform satisfies client needs, DRJ Plasttech regularly calibrates and aligns its molds.

6. Uneven Wall Thickness

Cause:

Inadequate material flow, problems with mold design, or uneven preform heating during blowing are frequently the causes of variations in wall thickness. Inadequate mold cavity balance may also be a factor.

Impact on Profitability:

Blow-out, weak bottle structure, and deformation during filling are more likely to occur in preforms with uneven walls. This may result in expensive returns or even end-user equipment damage.

Remedy:

- Make sure the cavities are balanced and the molds are heated uniformly.

- Preform weight distribution should be calibrated using material dosing systems.

- Monitor and modify wall thickness using real-time sensors.

- Maintain appropriate PET preheat temperature to encourage consistent expansion.

To guarantee that preforms have consistent thickness for ideal blowing outcomes, DRJ Plasttech employs precise temperature control and cavity monitoring.

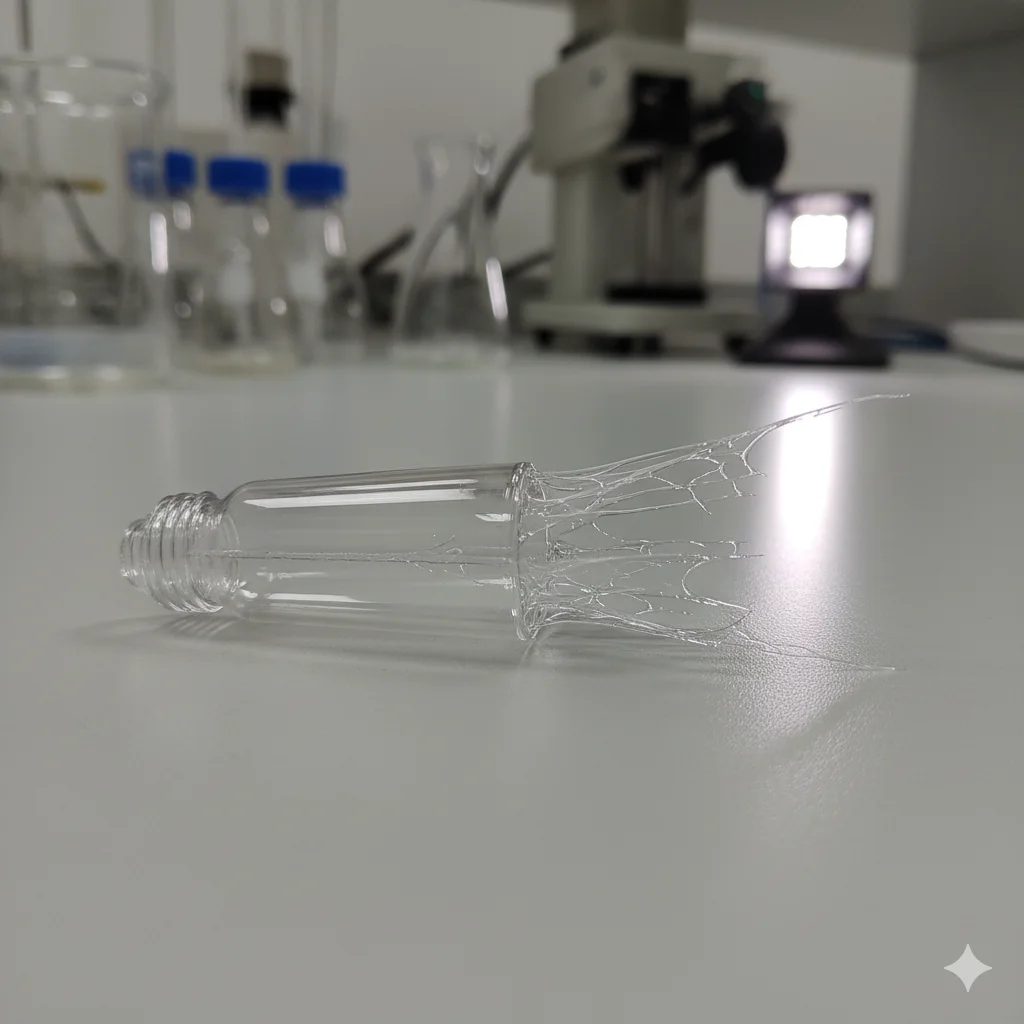

7. Crystallinity Defects

Cause:

Incorrect heating during the production of preforms made from polyethylene terephthalate (PET) and rapid cooling can develop crystallinity throughout the material, causing a cloudy appearance, decreased clarity, and compromised mechanical properties.

Impact on Profitability:

Cotton-cloudy preforms do not look visually appealing and may not meet quality standards in cosmetic or beverage industries. For example, extreme amounts of crystallinity often cause preforms to fail during the blowing phase (for example, during bottle blowing).

Remedy:

- It is important to ensure that optimum processing temperatures have been used when heating preforms during the manufacturing process.

- Ensure that preform cooling is done using a controlled or “slow cooling” process, to maintain the lack of crystallinity.

- Avoid overheating preforms or leaving them in the injection barrel for extended periods of time.

By maintaining all the preforms’ temperature zones and cooling cycles, DRJ Plasttech produces clear and defect-free preforms that can be used for high-clarity applications.

Ways DRJ Plasttech Prevents Defects in PET Preforms

DRJ Plasttech has developed an approach that minimizes defects at all stages of the production cycle by integrating technology, quality control, and expertise.

Advanced Technology

DRJ Plasttechs Injection Moulding Lines are the best available to produce the best preforms with the lowest number of defects. Computerised Control enables the operator to adjust the temperature, pressure, and shot size range on the fly to produce the best possible preform.

Strict Quality Control

DRJ Plasttech has established a system of inline inspection and cut-off inspection throughout the production line for every preform before they are packaged to ensure they meet our exacting quality standards.

Expert Technicians

DRJ Plasttech employs a team of highly-trained technicians who continuously monitor for defects. They can fine-tune their machines while they are running to meet our quality control standards.

Custom Solutions

DRJ Plasttech works closely with each of our customers to develop a preform tailored to their specific needs, including dimensions, weight, colour, and all parameters, which will help to eliminate defects in the downstream blow moulding process.

To Conclude

While you might view the defects present in your PET preforms as being minimal, their overwhelming impact on your production efficiency (as well as their impact on your revenue) could be extensive. For example, the presence of black specks, air bubbles, and excessive crystallinity will not only create inventory that cannot be sold but will also negatively affect customer loyalty and profitability.

We, at DRJ Plasttech, do not just produce; we create quality in all of our preform products through precision engineering, expert oversight, and rigorous quality assurance. From resin selection through the thorough inspection of finished product, we have developed an integrated process to eliminate your defects and improve your profit margin.

When you choose DRJ Plasttech for your precision-engineered PET preforms, you will never have to worry about preventing defects from cutting into your profit margins.

Top 10 FAQs on PET Preform Defects

1. What are the most usual types of Defects in PET Preforms?

The most usual types of Defects in PET Preforms are black specks, bubbles, yellowing, short shots, flash, uneven wall thickness, and crystallinity problems.

2. How do you prevent Black Specks in PET Prefroms?

By using clean raw materials, performing regular barrel purging, and keeping equipment uncontaminated.

3. What is the cause of Bubbles in PET preforms?

The Bubbles are usually caused by moisture remaining in the PET resin; therefore, properly drying out the resin before the Injection is very important

4. What is the effect of Heating on the Quality of PET Preforms?

Not heating correctly may lead to yellowing, crystallinity problems, and uneven wall thickness. Following the proper temperature while heating the PET preform promotes better clarity and strength.

5. What to do to remedy the yellowing of PET preforms?

By reducing the time during which the resin remains in the barrel while being heated, optimising the injection temperature, and ensuring the resin does not overheat.

6. Why is it that PET preforms sometimes show flash?

Flash occurs when the two halves of a mould do not properly meet because they have been worn down or there is too much pressure applied to them. Keeping your moulds maintained will help eliminate this problem.

7. How to fix the uneven thickness of the wall of a preform?

Make sure the mould cavities are balanced, maintain uniformity in heating of the preform, and use accurate dosing equipment to fill the preform.

8. What is the crystallinity of a PET preform?

The crystallinity of a PET preform is how the molecules of PET have been aligned in structure. If the cooling or heating of a PET preform is incorrect, a molecule will be partially crystallised and lose its clarity and strength.

9. What methods does DRJ Plasttech use to create defect-free PET preforms?

To produce defect-free PET preforms, DRJ Plasttech uses state-of-the-art machines in conjunction with stringent quality control processes, trained personnel, and continues its process optimisation program.

10. Which industries take advantage of defect-free PET preforms the most?

Many industries, including beverage, edible oils, cosmetics, and pharmaceuticals, rely on defect-free preforms to ensure the integrity and compliance of their packaging.

Ready to Eliminate Defects From Your Supply Chain?

If you are experiencing problems with any of the issues identified above, DRJ Plasttech can assist in lowering your scrap rate, improving your productivity, and providing you with a continual supply of high-quality PET preforms.