For many water bottling and packaging businesses, the temptation to invest in a PET preform machine can be strong. Owning your own preform production equipment promises independence, customisation, and control. But is it truly worth it?

At DRJ Plasttech, we’ve seen the full picture from both sides: as a leading PET preform supplier in Gujarat and as experts who’ve helped companies evaluate the viability of in-house production.

In this guide, we’ll unpack what’s worth investing in, what could become a financial sinkhole, and smarter alternatives that reduce risk while meeting your production goals.

Table of Contents

Understanding the Real Cost of a PET Preform Machine

5 Operational Challenges with In-House Machines

When Buying a PET Preform Machine Is Worth It

Smarter Alternatives to Buying a PET Preform Machine

The Financial Math: Total Cost of Ownership

Long-Term Strategy: Scaling Without Overextending

Why DRJ Plasttech is a Smarter Alternative

Final Verdict: Outsourcing or Buying — What’s Right for You?

Smarter Growth Starts with Smarter Partnerships

FAQs: Buying PET Preform Machinery

Understanding the Real Cost of a PET Preform Machine

Before you make a major investment, it’s critical to understand what buying a pet preform machine actually involves. It’s not just a one-time purchase; it’s a full ecosystem that requires space, skilled operators, maintenance, and consistent raw material sourcing.

The Machine Itself

A new, high-quality preform pet bottle machine from a top-tier brand can range anywhere from ₹20 lakh to ₹1 crore+, depending on capacity and technology.

Average pet preform making machine price in India:

- Small-scale (up to 150 tons): ₹25 – ₹45 lakh

- Mid-size (150–250 tons): ₹45 – ₹70 lakh

- High-volume (250+ tons): ₹70 lakh – ₹1.2 crore+

This doesn’t include installation, shipping, or mould costs.

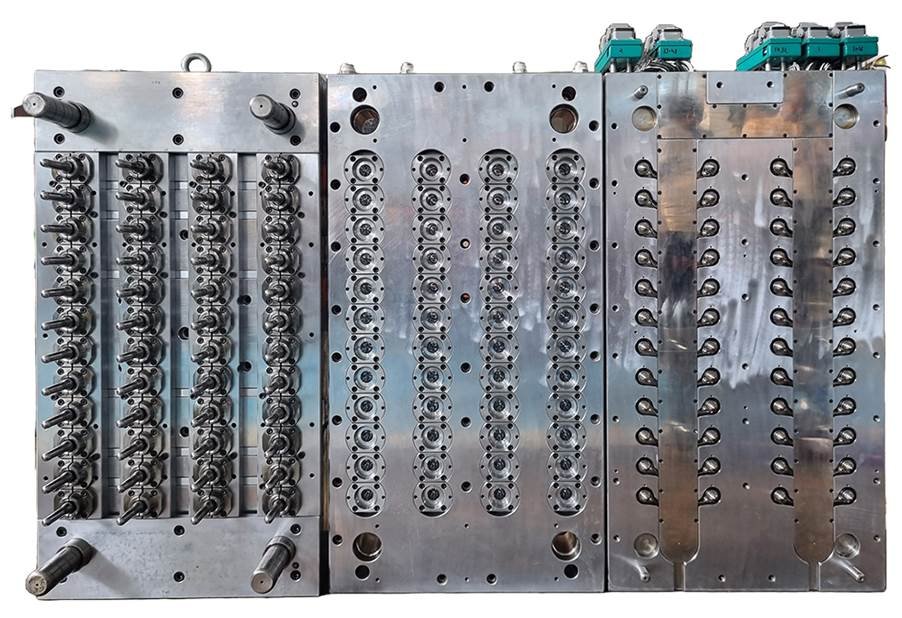

Custom Moulds & Tooling

Each PET preform machine needs custom moulds suited to your bottle neck sizes and volume specifications. Mold fabrication can cost ₹5 – ₹15 lakh per format, depending on complexity.

And if you want to produce more than one neck finish? Add ₹10–₹20 lakh more.

Infrastructure & Setup

To support a preform line, you’ll need:

- Climate-controlled storage for PET resin

- High-voltage electrical setup

- Compressed air and chiller systems

- Skilled labour for operations and maintenance

This can easily add another ₹10–₹25 lakh to your startup budget.

5 Operational Challenges with In-House Machines

Once you’re up and running, the learning curve doesn’t flatten overnight. Many companies underestimate how demanding it is to manage preform pet bottle machine operations at scale.

1. Skilled Labor is Hard to Find

PET machines are not “plug and play.” You’ll need trained technicians who understand:

- Resin melting points and viscosity

- Machine calibration and cycle timing

- Quality inspection protocols

Skilled labour in this niche is both scarce and expensive.

2. Downtime is Inevitable

Even top machines break down. Whether it’s maintenance or mechanical failure, any unplanned downtime:

- Delays production

- Disrupts delivery timelines

- Risks inventory shortages

If your customers rely on fast delivery, these issues can impact your bottom line and your reputation.

3. Resin Waste is a Cost Drain

New operators often face high waste rates due to improper machine calibration, undercooling, or short-shot issues. This wasted PET resin can quickly rack up thousands in losses each month, especially when resin prices spike.

4. Quality Control and Risk Management

Perhaps the biggest difference between outsourcing to experts like DRJ Plasttech and making your own preforms is quality control.

5. Inconsistent Quality from Inexperienced Teams

Producing consistent preforms with the right weight, transparency, strength, and finish isn’t easy. Minor deviations in moisture or melt temperature can lead to:

- Brittle necks

- Dimensional errors

- Blush marks and defects

When Buying a PET Preform Machine Is Worth It

We’re not here to discourage all in-house manufacturing. In some cases, buying a pet preform machine may be a solid investment:

- You have consistent high-volume demand

- You’ve secured a long-term resin supply

- You have the infrastructure and trained labour

- You want tight control over proprietary bottle designs

- Your per-unit costs with outsourcing are too high for your scale

In these cases, investing in a preform pet bottle machine could pay off in the long term, but only with a clear growth plan and technical backing.

When It’s Not Worth It

If any of the following are true, hold off on buying machinery:

- Your demand is seasonal or fluctuates

- You can’t afford full-time technical staff

- Your capital could be better spent on marketing, distribution, or finished bottling lines

- You’re unfamiliar with resin procurement and QA processes

In such cases, outsourcing to a trusted partner like DRJ Plasttech is far more efficient.

Smarter Alternatives to Buying a PET Preform Machine

Now for the smarter path: outsourcing strategically while maintaining control over your packaging supply chain.

At DRJ Plasttech, we provide flexible PET preform supply options tailored to your business:

Volume-Based Pricing

With daily capacity of 15+ tons, we offer better pet preform price per kg than smaller in-house setups. Bulk orders come with additional discounts and delivery scheduling.

Preform Customisation (Without Machinery Investment)

Need unique neck finishes or custom branding? We offer mould development services so you get the packaging look you want without owning a preform pet bottle machine yourself.

Quality Guarantee, Always

We back every order with full quality assurance, ensuring your bottles perform in blow moulding machines with zero defects or returns.

The Financial Math: Total Cost of Ownership

To make an informed decision, let’s break down the total cost of owning a PET preform machine over five years versus outsourcing to a specialised manufacturer like DRJ Plasttech.

Scenario A: In-House PET Preform Manufacturing

| Item | Estimated Cost (INR) |

| PET Preform Machine | ₹60,00,000 |

| Mold Setup (2 sizes) | ₹15,00,000 |

| Infrastructure Setup | ₹20,00,000 |

| Skilled Labor (5 years) | ₹30,00,000 |

| Maintenance & Parts | ₹7,00,000 |

| Resin Wastage Loss (avg. 3%) | ₹10,00,000 |

| Total | ₹1,42,00,000 |

Even with modest volumes, you’re looking at ₹1.4 crore+ in ownership costs, not including interest or loan repayments. And that assumes smooth operations with no downtime-related losses.

Scenario B: Outsourcing to DRJ Plasttech

| Item | Estimated Cost (INR) |

| Preform Purchases (₹85/kg avg.) | ₹85,00,000 (over 5 years) |

| Transport & Logistics | ₹2,00,000 |

| Quality Control & Returns | ₹0 (covered by DRJ) |

| Machine Downtime | ₹0 |

| Maintenance | ₹0 |

| Total | ₹87,00,000 |

With outsourcing, you reduce your capital exposure by nearly ₹55 lakhs. Plus, you avoid the stress of managing complex operations.

Long-Term Strategy: Scaling Without Overextending

For many bottling businesses, the key to sustainable growth is scalability without overcommitment. PET preform manufacturing, while attractive on the surface, often becomes a bottleneck due to:

- Unforeseen capital expenditures

- Supply chain inefficiencies

- Operational disruptions

By partnering with a full-service preform supplier, you can:

- Expand into new markets faster

- Adjust volumes seasonally

- Focus on sales, branding, and distribution

- Invest in consumer-facing growth instead of backend complexity

At DRJ Plasttech, we provide tailored supply models whether you’re launching a new water brand or expanding an FMCG portfolio across states.

Why DRJ Plasttech is a Smarter Alternative

We’re not just a PET preform manufacturer, we’re a strategic extension of your business.

A. Capacity You Can Count On

Our 40,000 sq. ft facility produces 15+ tons of PET preforms per day, meaning no delays, even during peak seasons.

B. Consistency You Can Trust

Our rigorous QA ensures:

- Zero contamination

- Uniform wall thickness

- Exact weight and dimensions

- Blow moulding compatibility

You won’t need to worry about trial runs or inconsistent batches that affect final bottle quality.

C. Competitive Pricing Structure

With economies of scale and a transparent pricing model, we offer one of the most competitive pet preform price per kg rates in India without cutting corners on material or quality.

Whether you’re ordering 5 tons or 500 kg, our pet preform price in India is optimised for value, reliability, and repeatability.

D. Innovation for Future Growth

From light-weighting to eco-friendly resin compatibility, our team is constantly exploring new product lines to meet the evolving needs of packaging businesses.

Final Verdict: Outsourcing or Buying — What’s Right for You?

Here’s how to decide:

| Factor | In-House | Outsourcing |

| Capital Availability | High Required | Low |

| Volume Consistency | Required | Flexible |

| Technical Expertise | Essential | Not Required |

| Time to Market | Slower | Faster |

| Operational Risk | High | Minimal |

| Scalability | Fixed | Adaptive |

| Focus | Manufacturing | Sales & Growth |

In-house PET preform manufacturing only makes sense if:

- You are a large-scale operator with consistent volume

- You have the capital and technical bandwidth

- You want total control over your packaging line

Outsourcing to DRJ Plasttech is the right choice if:

- You want to reduce capital risk

- You want flexibility and reliable supply

- You want to scale smart, not fast

Smarter Growth Starts with Smarter Partnerships

At DRJ Plasttech, we believe in removing complexity from your supply chain. Our clients choose us not just because of our quality PET preforms, but because we simplify growth.

With tailored production schedules, logistics support, and competitive PET preform price in India, we help you scale faster, reduce costs, and focus on what matters: growing your brand.

If you’re still unsure whether to buy a PET preform machine or outsource, our team would be happy to guide you through a custom ROI analysis.

Let’s talk numbers, possibilities, and how to make the smartest investment for your business, without the guesswork.

FAQs: Buying PET Preform Machinery

1. What is a PET preform machine used for?

A PET preform machine is used to manufacture the initial form of PET bottles, called preforms, through an injection moulding process. These are later blow-moulded into finished bottles.

2. What is the average PET preform making machine price in India?

The price can range from ₹35 lakhs to over ₹1 crore depending on the brand, tonnage, cavity count, and automation features.

3. Is it cheaper to buy a preform PET bottle machine or outsource production?

It depends on your scale. Outsourcing is often more cost-effective for small to mid-sized businesses, avoiding high initial capital, labour, and maintenance costs.

4. What factors affect PET preform machine costs?

Key factors include machine tonnage, cavity size, mould design, level of automation, energy efficiency, and after-sales support.

5. Can I start PET preform production with a single machine?

Yes, but it’s important to consider consistent raw material supply, technical staff, maintenance capabilities, and space for operation.

6. What’s the lifespan of a PET preform machine?

With regular maintenance, a PET preform machine can last 10–15 years, though productivity and energy efficiency may decline over time.

7. Are there hidden costs in running PET preform machinery?

Yes — including mold maintenance, electricity, skilled labour, cooling systems, and potential downtime due to technical issues.

8. What are smarter alternatives to buying PET preform machines?

Partnering with a reliable manufacturer like DRJ Plasttech ensures consistent quality, reduced operational complexity, and lower overall costs.

9. Is local machine servicing easily available in India?

Service availability depends on the manufacturer. While top brands offer local support, imported machinery can lead to long wait times and higher costs.

10. Why choose DRJ Plasttech over investing in machinery?

We offer scalable supply, unmatched quality control, and flexible ordering without the massive capital investment, helping businesses focus on growth and not machinery headaches.