In the highly competitive world of packaging, precision and consistency in PET preform manufacturing aren’t just desirable: they’re essential. For businesses relying on PET bottles for beverages, edible oils, or other liquids, even a slight defect in preforms can lead to massive losses in terms of product rejection, production delays, and customer dissatisfaction.

As one of Gujarat’s leading PET preform manufacturers, DRJ Plasttech understands the real cost of poor-quality preforms. With over 15 tons of high-quality preforms produced daily at our 40,000 sq ft Surat facility, we’ve seen how consistent quality control can directly boost our clients’ profitability.

In this blog, we uncover 7 common PET preform defects that silently eat into your profits, and more importantly, we show you how to fix them using proven methods based on DRJ Plasttech’s manufacturing expertise.

Table of Contents

7 Preform Defects Killing Your Profits and How to Fix Them

3. Yellowing or Discolouration

Intermission: Why Quality Control Matters

How DRJ Plasttech Minimises PET Preform Defects

Top 10 FAQs on PET Preform Defects

Ready to Eliminate Defects From Your Supply Chain?

Let’s dive straight into the most common PET preform defects:

1. Black Specks in Preforms

Cause:

Black specks usually originate from degraded PET resin, leftover impurities in the injection barrel, or contamination from previous production runs. Even small particles of dust or carbonised material can manifest as dark specks within the preform.

Impact on Profitability:

This defect reduces visual clarity and quality perception, especially for transparent bottles. In food-grade and pharmaceutical packaging, black specks can result in total rejection of batches due to contamination concerns.

Remedy:

- Maintain strict hygiene in raw material handling.

- Use food-grade virgin PET resin.

- Increase the frequency of barrel purging during production changeovers.

- Install filters and screens in the melt flow path to capture contaminants.

At DRJ Plasttech, our advanced cleaning systems and quality checks ensure black specks are identified and corrected at the source.

2. Bubbles in Preforms

Cause:

The presence of moisture in PET resin is the leading cause of air bubbles in preforms. PET is hygroscopic, meaning it absorbs moisture from the air. If not dried properly before processing, this moisture turns into vapour during injection, creating bubbles.

Impact on Profitability:

Bubbles compromise the structural integrity of the bottle and can lead to failure during blowing or filling. In critical applications like carbonated drinks, this can cause leakage or rupture, leading to costly rework and wastage.

Remedy:

- Dry the resin thoroughly using dehumidifying dryers to reduce moisture content below 0.005%.

- Monitor dryer temperatures and drying duration consistently.

- Store PET granules in moisture-proof containers.

DRJ Plasttech utilises advanced drying systems to ensure all preforms are bubble-free and structurally sound.

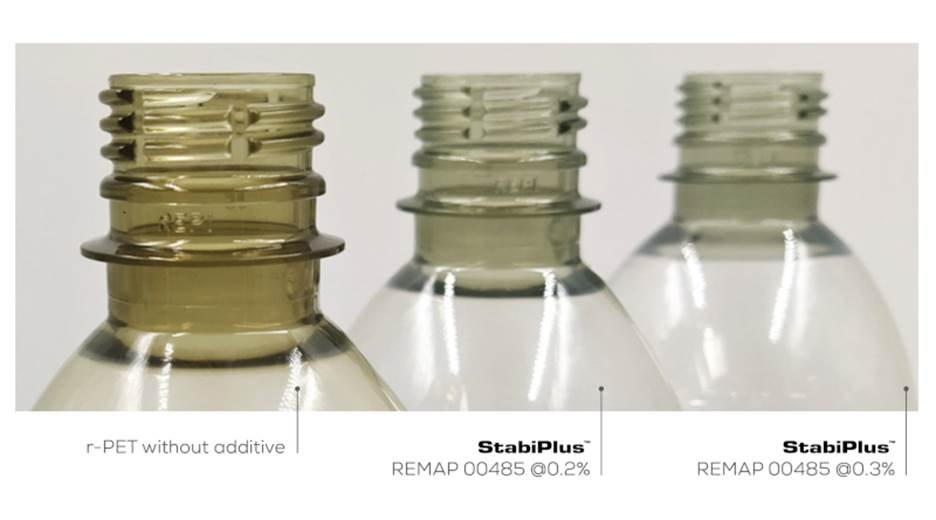

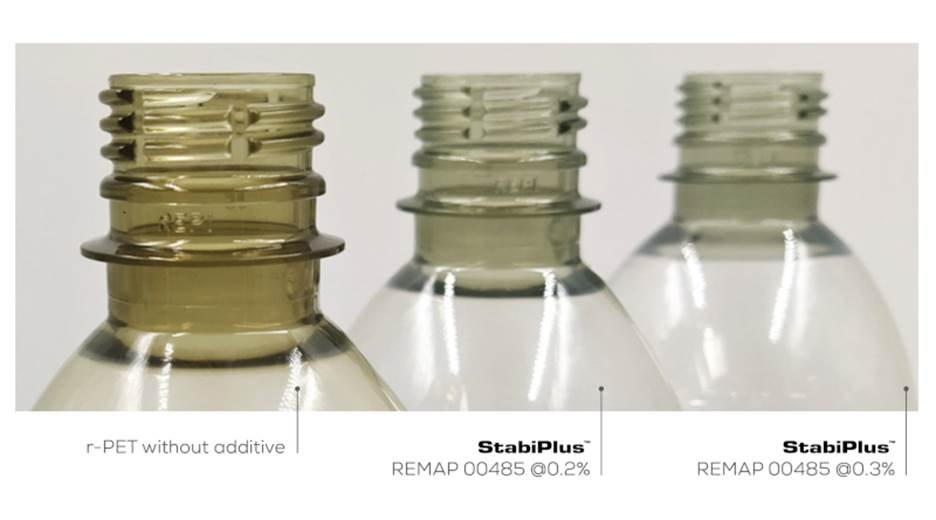

3. Yellowing or Discolouration

Cause:

Yellowing of PET preforms often results from overheating during injection moulding. It may also occur due to prolonged residence time in the barrel or recycled resin with excessive impurities.

Impact on Profitability:

Discoloured preforms reduce product appeal, especially in transparent or lightly tinted packaging. They often lead to rejections during quality inspections or fail to meet client colour DRJ specifications.

Remedy:

- Optimise the PET preform heating temperature to stay within the ideal range (typically 270°C to 290°C depending on resin grade).

- Avoid long idle times in the barrel.

- Use high-quality virgin material or well-sorted recycled resin.

- Monitor back pressure and screw speed.

At DRJ Plasttech, our computerised temperature monitoring ensures consistent heat profiles for every production batch, minimising discolouration risk.

4. Short Shots

Cause:

Short shots occur when the mould cavity is not fully filled during the injection process. This is typically caused by insufficient injection pressure, improper shot size, or blocked gates and runners.

Impact on Profitability:

Incomplete preforms are unusable and must be scrapped. More critically, they can go unnoticed and reach the blowing stage, causing equipment downtime and increased waste.

Remedy:

- Increase injection pressure to ensure full cavity fill.

- Check and adjust shot size per cavity specifications.

- Regularly clean and inspect runners, gates, and nozzles.

- Ensure proper venting in the mould to prevent air traps.

Our preventive maintenance schedule at DRJ Plasttech ensures moulds are kept in optimal condition to eliminate issues like short shots.

Intermission: Why Quality Control Matters

At DRJ Plasttech, we don’t just produce PET preforms; we engineer consistency. Our facility is equipped with inline inspection systems, mold temperature controllers, and precise dosing systems to guarantee every preform matches exact customer specifications.

Need defect-free preforms delivered consistently?

Get in touch with our team to discuss your packaging requirements and request a free consultation.

5. Flash at Parting Line

Cause:

Flash occurs when excess plastic leaks out between mould halves during injection. It’s typically the result of worn mould components, poor mould alignment, or excessive injection pressure.

Impact on Profitability:

Even small flashes need trimming or post-processing, which adds labour and cost. Inconsistent flash removal can damage preform necks, leading to bottle leakage or capping issues.

Remedy:

- Inspect and maintain moulds regularly to ensure tight alignment and seal integrity.

- Reduce injection pressure to optimal levels without compromising fill.

- Ensure proper mould clamping force is applied to minimise separation.

At DRJ Plasttech, our moulds undergo routine calibration and alignment to eliminate the risk of flash, ensuring every preform meets customer requirements.

6. Uneven Wall Thickness

Cause:

Variations in wall thickness are often due to improper material flow, mould design issues, or inconsistent heating of the preform during blowing. Poor mould cavity balance can also contribute.

Impact on Profitability:

Preforms with uneven walls are at higher risk of blow-out, weak bottle structure, or deformation during filling. This can lead to costly returns or even damage to end-user equipment.

Remedy:

- Ensure moulds are evenly heated and cavities are balanced.

- Calibrate preform weight distribution through material dosing systems.

- Use real-time sensors to monitor and adjust wall thickness.

- Maintain correct PET preform heating temperature to promote uniform expansion.

DRJ Plasttech uses precision temperature control and cavity monitoring to ensure preforms have uniform thickness for perfect blowing results.

7. Crystallinity Defects

Cause:

Incorrect PET preform heating temperature or overly fast cooling cycles can result in partial crystallisation. This leads to cloudiness, poor transparency, and reduced mechanical performance.

Impact on Profitability:

Crystallised preforms reduce shelf appeal and may not pass quality checks in cosmetic or beverage packaging industries. In severe cases, these preforms fail during bottle blowing.

Remedy:

- Adjust the preform heating temperature in the injection machine within the optimal processing window.

- Use controlled, gradual cooling methods to preserve amorphous clarity.

- Avoid overheating or long dwell times in the injection barrel.

By maintaining precise temperature zones and cooling cycles, DRJ Plasttech consistently produces clear, defect-free preforms suitable for high-clarity applications.

How DRJ Plasttech Minimises PET Preform Defects

At DRJ Plasttech, we’ve engineered every part of our process to minimise defects before they occur. Here’s how:

- Advanced Technology:

We operate state-of-the-art injection moulding lines with computerised controls for temperature, pressure, and shot size. - Rigorous Quality Control:

Inline inspection systems and manual checks at multiple production points ensure that every preform meets exact standards. - Skilled Technicians:

Our experienced team proactively monitors defect trends and fine-tunes machine parameters in real-time. - Tailored Solutions:

We collaborate with customers to adjust preform dimensions, weight, and colour based on application needs, helping reduce downstream defects during blowing.

To Conclude

Defects in PET preforms may seem minor at first glance, but their cumulative effect on your packaging line, production efficiency, and bottom line can be significant. Issues like bubbles, black specks, and crystallinity not only result in rejected stock but also damage customer trust and profitability.

At DRJ Plasttech, we go beyond manufacturing, we engineer quality into every preform with precision, expertise, and care. From resin selection to final inspection, every stage of our process is designed to eliminate defects and maximise your returns.

Don’t let preventable defects eat into your margins. Choose DRJ Plasttech for precision-engineered PET preforms that work as hard as you do.

Top 10 FAQs on PET Preform Defects

1. What are the most common PET preform defects?

The most common PET preform defects include black specks, bubbles, yellowing, short shots, flash, uneven wall thickness, and crystallinity issues.

2. How can black specks be prevented in PET preforms?

Use clean raw materials, implement regular barrel purging, and ensure your equipment is free from contamination.

3. What causes bubbles in PET preforms?

Bubbles typically result from moisture in the PET resin. Proper drying before injection is essential.

4. How does PET preform heating temperature affect quality?

Incorrect heating can cause yellowing, crystallinity issues, and uneven wall thickness. Maintaining optimal temperature ensures clarity and strength.

5. What is the remedy for yellowing in PET preforms?

Reduce barrel residence time, optimise injection temperature, and avoid overheating the resin.

6. Why does flash appear on PET preforms?

Flash appears when mold halves don’t seal properly due to wear or excessive pressure. Mold maintenance is key.

7. How can uneven wall thickness be fixed?

Ensure mould cavity balance, maintain consistent preform heating, and use precise dosing systems.

8. What is crystallinity in PET preforms?

Crystallinity refers to the structural arrangement of PET molecules. Improper cooling or heating can lead to partial crystallisation, reducing clarity and strength.

9. How does DRJ Plasttech ensure defect-free preforms?

By using modern machines, strict quality control protocols, skilled technicians, and continuous process optimisation.

10. What industries benefit most from defect-free PET preforms?

Beverage, edible oil, cosmetic, and pharmaceutical industries rely heavily on defect-free preforms to ensure packaging integrity and compliance.

Ready to Eliminate Defects From Your Supply Chain?

If you’re struggling with any of the issues listed above, DRJ Plasttech can help you reduce scrap rates, improve productivity, and ensure consistent supply of high-quality PET preforms.